38 nickel copper phase diagram

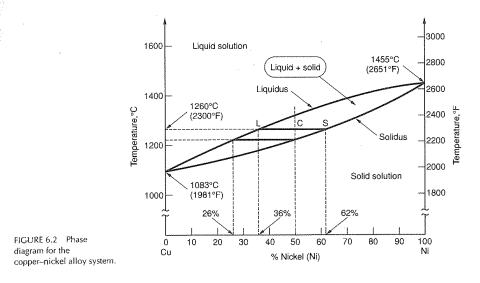

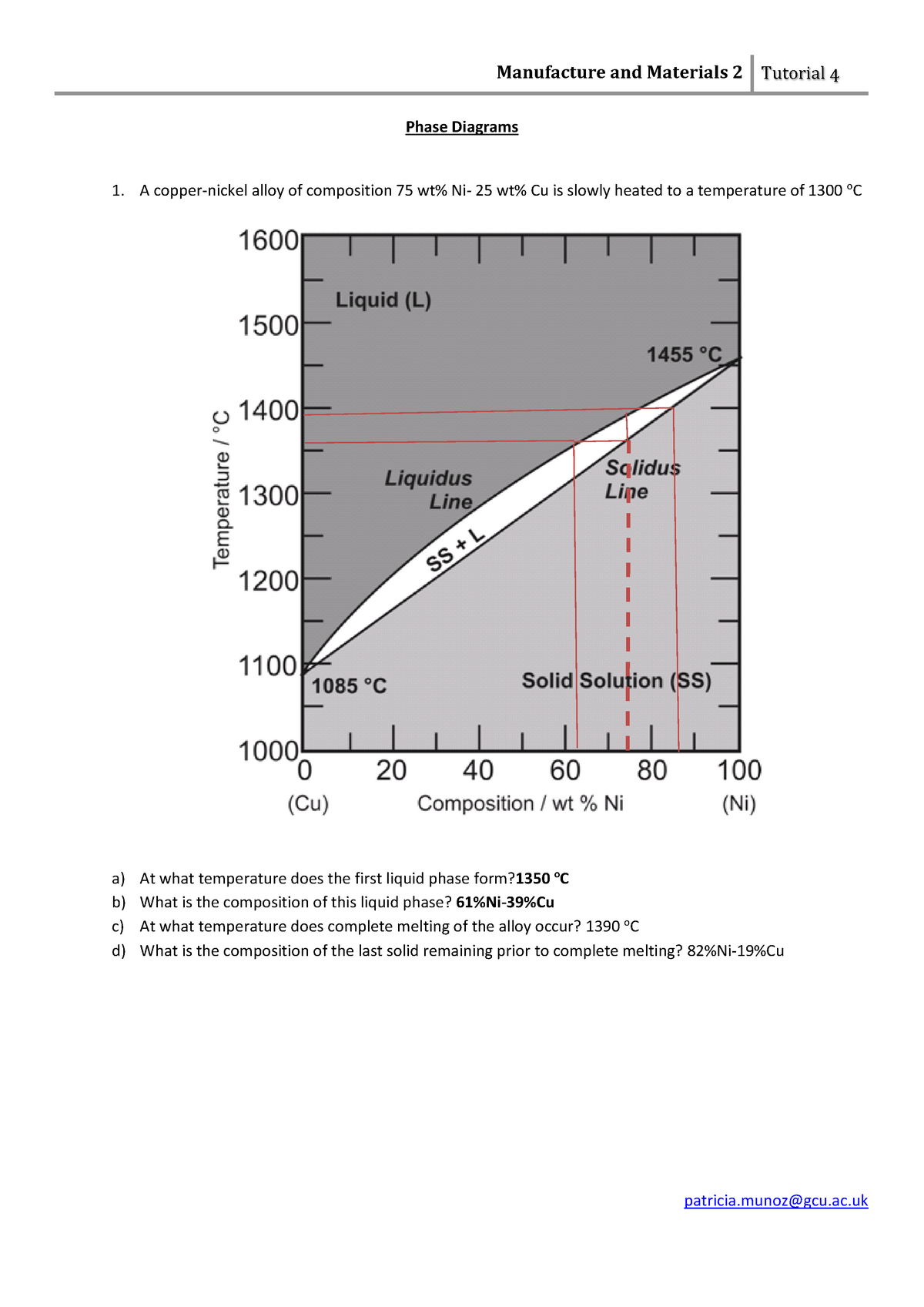

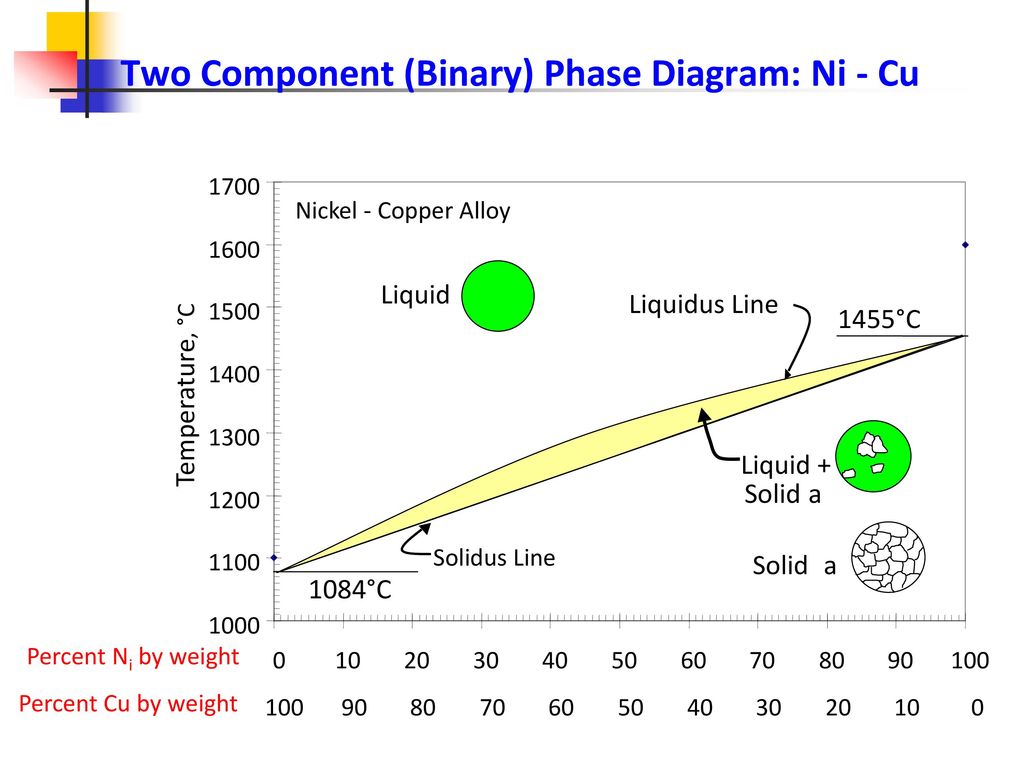

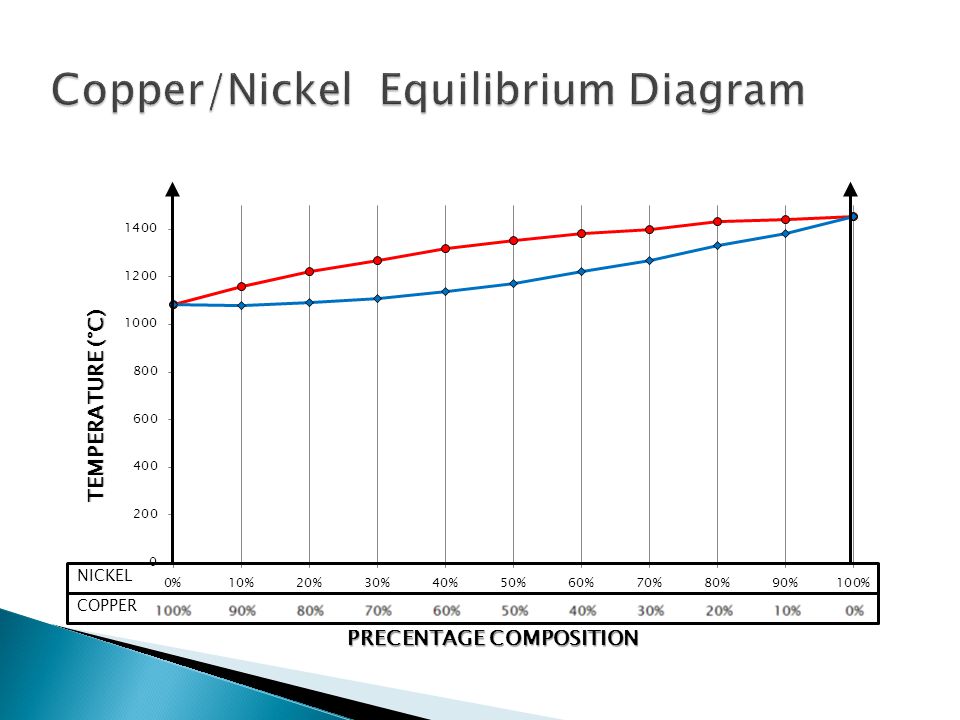

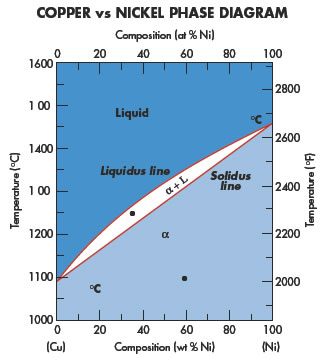

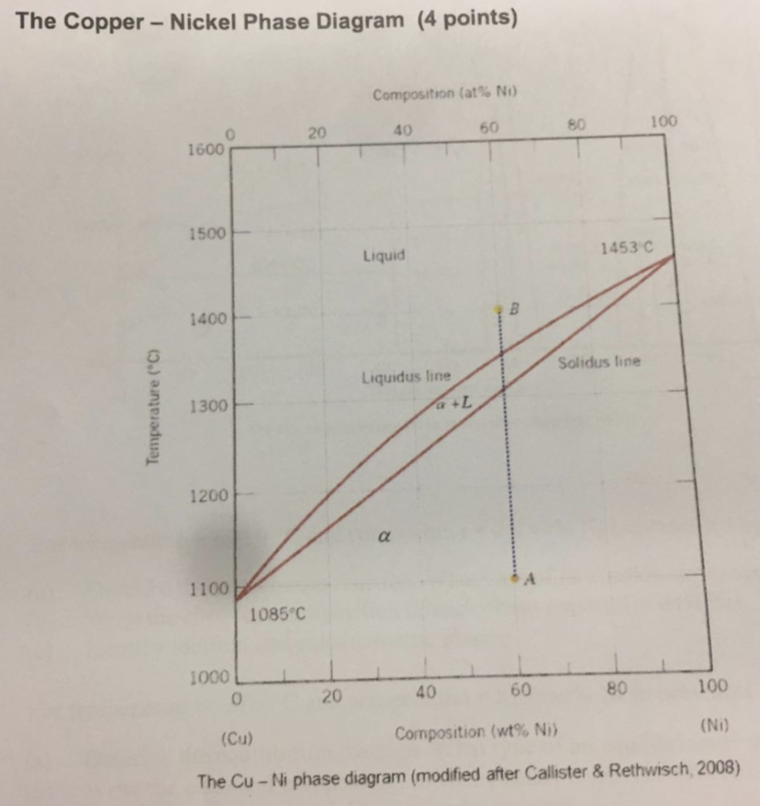

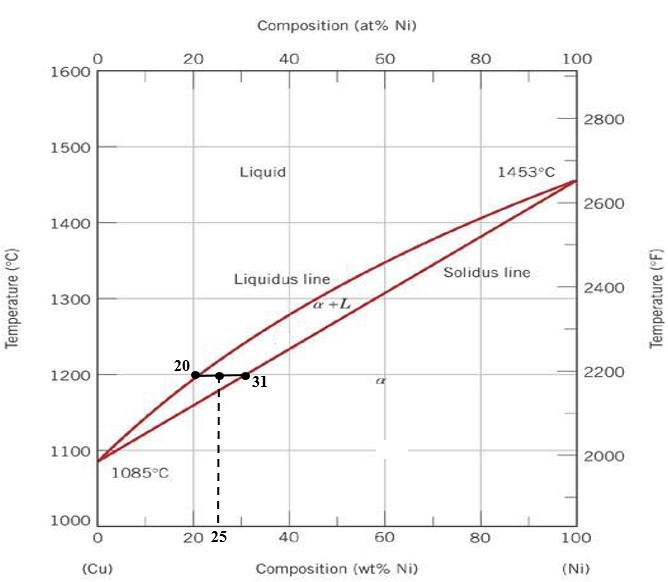

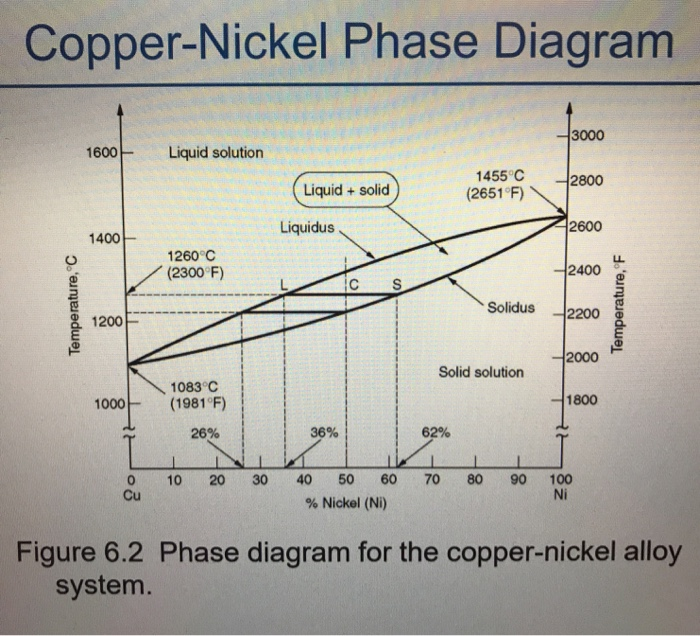

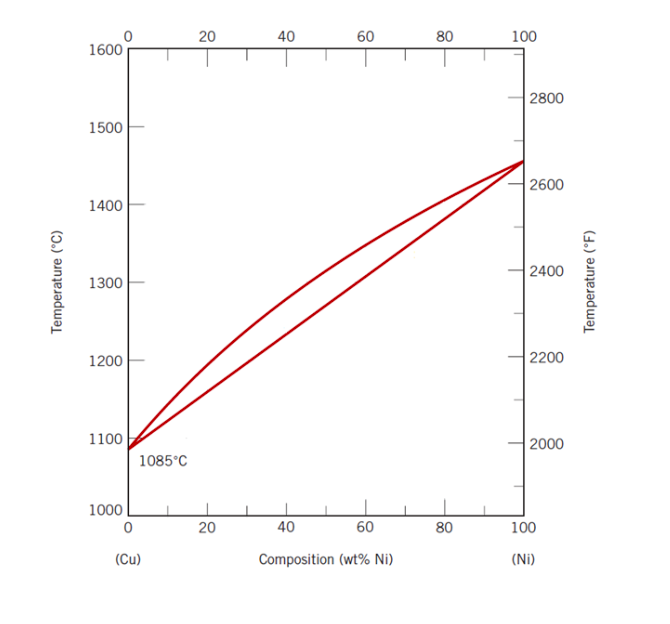

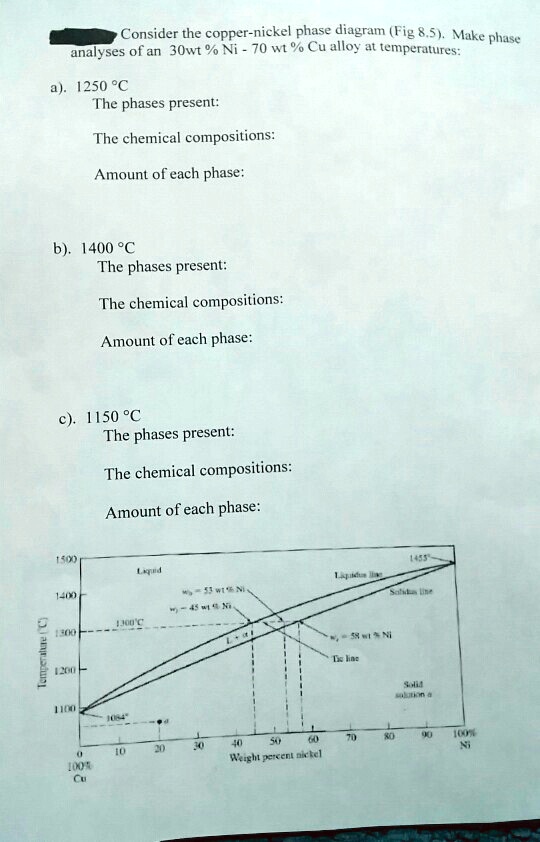

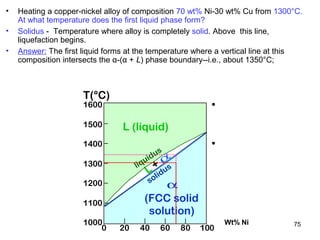

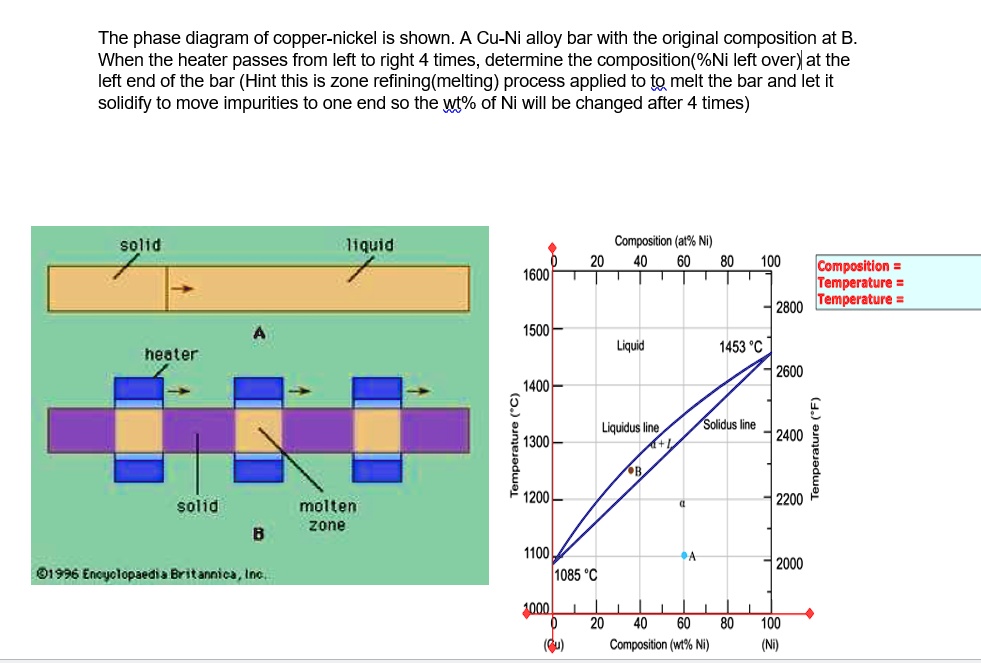

Solved For the copper-nickel phase diagram (see Figure ... Transcribed image text: For the copper-nickel phase diagram (see Figure), find the compositions of the liquid and solid phases for a nominal composition of 70% Ni and 30% Cu at 1371°C (2500°F). 43000 1600 Liquid solution Liquid solid 1455-6 (2651-F) 2800 1400 Liquidus 2800 1260.C (2300-F) 42400 IC Temperature, Solidus Temperature, 1200 42200 2000 Solid solution 1083 (1981-F) 1000 1800 26% 36 ... Phase Diagrams & Computational Thermodynamics - NIST In recent years, our effort has focused on some specific families of alloys, including nickel-based superalloys for aerospace applications and high-temperature and lead-free solders. A phase diagram is the representation of phase equilibria present in a system as function of the controlling variables, typically composition and temperature.

Solved Use the phase diagram below. A copper-nickel alloy ... Transcribed image text: Use the phase diagram below. A copper-nickel alloy (53 wt% Ni and 47 wt% Cu) is 1) heated to 1400°C, and then 2) rapidly cooled to 1300 OC and keep at this temperature for long enough time to reach to an equilibrium condition, and then 3) the temperature is quenched to room temperature What is the weight fraction of the phase/s after process 3)? 1500 1455 Liquid 1400 00-53 wt % Ni 4:45wt%Ni 1300°C 1300 58wt%Ni E 1200 Solid solution α 1100 1084 1020 ...

Nickel copper phase diagram

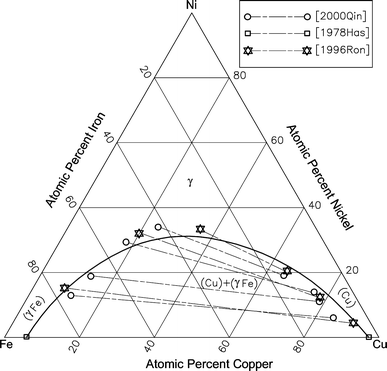

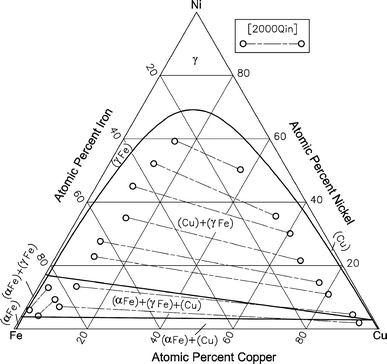

Cu-Fe-Ni (Copper-Iron-Nickel) - Journal of Phase ... The Cu-Ni phase diagram [ 2007Tur] depicts a continuous fcc solid solution between Cu and Ni. The solid solution breaks into Cu-rich and Ni-rich fcc phases at low temperatures. The Fe-Ni phase diagram [ 1991Swa] is characterized by a very narrow solidification range, with a peritectic reaction between (δFe) and liquid yielding (γFe). PDF Chapter 9: Phase Diagrams - Florida International University Phase Diagrams: composition of phases • Rule 2: If we know T and Co, then we know:--the composition of each phase. • Examples: TA A 35 Co 32 CL At TA = 1320°C: Only Liquid ( L) CL = C o ( = 35 wt% Ni) At TB = 1250°C: Both α and L CL = Cliquidus ( = 32 wt% Ni here) Cα = Csolidus ( = 43 wt% Ni here) At TD = 1190°C: Only Solid ( α) MECN 2010: Introduction to Copper Nickel Phase Diagram ... Introduction to the Cu-Ni phase diagram relating to the use of the Lever Rule for determining composition and phase weight percentages.

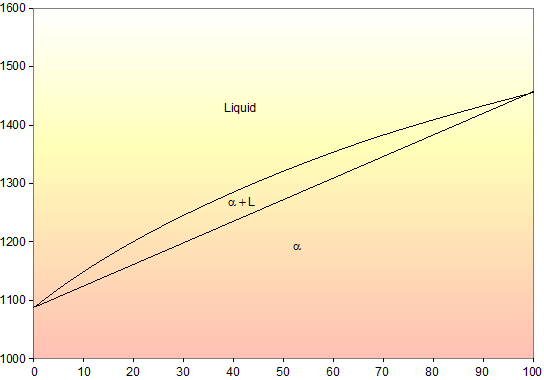

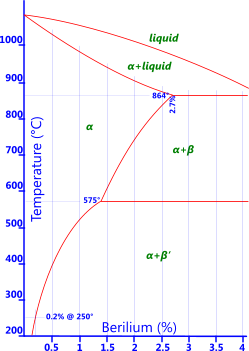

Nickel copper phase diagram. nglos324 - phasediagram - Princeton University The binary phase diagram shown for the copper-nickel alloy indicates that these materials can form both liquid and solid solutions over the full range of composition from Cu to Ni. Above 1728 K, the melting point of pure Ni the alloys ar in the liquid phase. Between 1728 K and 1357 K (the melting point of Cu) the alloys can be either solid or ... PDF Beryllium Copper Alloys at the left of the diagram where the alloy is in solid solution (phase ), a face centred cubic structure like copper. For the typical alloy CuBe1.9 (1.8 to 2% of beryllium) the alloy is in the phase between 720°C and 860°C. For industrial purposes the solution heat treatment is done between 750° and 800°C. By rapidly cooling the IRON--NICKEL--TUNGSTEN PHASE DIAGRAM. (Technical Report ... The slumping and distortion behavior of tungsten-nickel-iron (W-Ni-Fe) alloys containing 90 percent tungsten was studied. Additions of ruthenium, copper, cobalt, and hafnium either singly or in combination were made to a W-7 Ni-3 Fe alloy, and the sintering behavior of the alloys produced was observed as a function of sintering temperature and to some extent, the sintering time. Copper-Nickel Alloys: Properties, Processing, Applications Copper and nickel are adjacent to one another in the periodic system of elements, with atomic numbers 29 and 28 and atomic weights 63.54 and 68.71.The two elements are closely related and are completely miscible in both the liquid and solid state. Cu-Ni alloys crystallise over the whole concentration range in a face-centred cubic lattice.

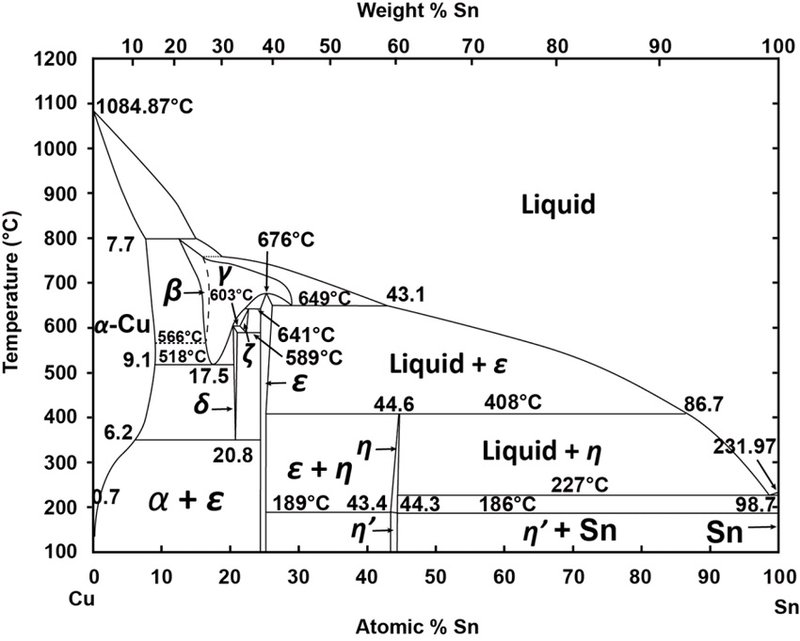

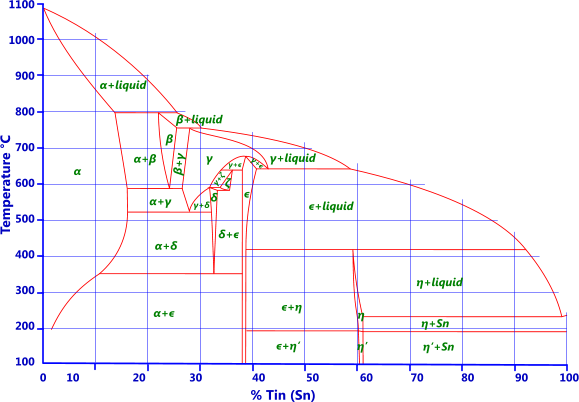

(PDF) Phase equilibria and thermodynamics of binary copper ... phase transformations. The excess Gibbs free energy of phases is described by the following equations: Δ G L, ex = xNi(1 - xNi) (14259 + 0.45T) J/mole for liquid alloy and Δ G (Cu, Ni), ex = xNi(1... Some Phase Diagrams - Technische Fakultät The copper - zinc phase diagram is a bit simpler than the copper - tin phase diagram but still complex enough. There are all kinds of brass' but typically we are at the copper-rich side. Of course, if we want to look at all copper alloys, we would need a bunch of more binary phase diagrams, in particular for the elements arsenic (As), antimony, (Sb), silver (Ag), and lead (Pb) since these are ... PDF EN380 Homework #6 Solution - United States Naval Academy EN380 Homework #6 Solution 1.The binary (two-component) phase diagram for copper-nickel alloys is shown below. A Cu - Ni alloy contains 30 wt. % Cu at a temperature of 1350 C. Find the following: (a)melting point for pure copper.1084 C (b)melting point for pure nickel.1455 C (c)wt. % Niin the (entire) binary alloy.70% Ni The Iron-Carbon Alloys And Fe-C Phase Diagram - MD ... The iron-carbon phase diagram and the iron-carbon systems are the most important binary systems in engineering. Steels, cast irons, and various kinds of applications are dependent on iron-carbon systems. We also explained the tin-lead phase diagram and nickel-copper phase diagrams which are also very important in metallurgy and engineering.

Binary Phase Diagrams - Cu-Ni System - YouTube This video explains binary phase diagrams, specifically the Cu-Ni System. For further studies: visit ... Copper-nickel phase diagram including the miscibility gap ... Copper-nickel phase diagram including the miscibility gap of the (Cu, Ni) phase: the dashed line denotes the boundary of magnetic transformation Source publication Phase equilibria and... Standards & Properties: Metallurgy of Copper-Base Alloys The copper-tin equilibrium phase diagram ( Figure 3) illustrates Cases (1) and (2). Figure 3. Copper-tin equilibrium phase diagram (Reference 2). Case (1) - Substitution Figure 4. Microstructure of a single-phase (alpha) copper-tin alloy (88Cu-8Sn-4Zn). Structure shows slip lines. Note also traces of the delta phase (darker islands) (Reference 2). Materials Science: Tutorials - Elsevier The phase diagram shown is the diagram for Cu-Ni, which is an isomorphous alloy system. Isomorphous systems are not common, although there are number of isomorphous systems used. The copper-nickel system is an example.

COPPER - NICKLE PHASE DIAGRAMS (LECTURE 9) Flashcards ... COPPER - NICKLE PHASE DIAGRAMS (LECTURE 9) STUDY Flashcards Learn Write Spell Test PLAY Match Gravity What is a phase diagram? Click card to see definition 👆 A diagram that shows the phase of a substance based upon the temperature and percentage composition of the composition (it could be solid, liquid, or even a mixture of the two)

Phase Diagram - Industrial Metallurgists Aluminum-Copper Phase Diagram Another commonly used phase diagram is the aluminum-copper phase diagram, which is useful for understanding precipitation strengthening in Al-Cu alloys. The amount of copper present in an alloy is plotted on the x-axis. The phase fields of interest are the Al, θ, and Al+θ phase fields on the left hand side.

Binary Phase Diagrams In Metallurgy - MD - Engineering Binary phase diagram is diagram that shows the compositional property and phase change with the changing temperature and the changing compositions of alloys that constitutes two of alloying compositions. One of the greatest examples of these binary phase systems are Nickel-copper system and the iron-carbon systems. Cu-Ni binary phase diagram.

PDF Chapter 7 Alloys with Nickel Al-Cu-Ni PHASE DIAGRAM This phase diagram is helpful in the analysis of 2618-type heat-resistant alloys and 339.0-type piston alloys that contain nickel, copper, and other alloying components (Tables 7.1 and 7.2). The ternary Al7Cu4Ni phase forms in the aluminum corner of the Al-Cu-Ni system.

Solid Solution of Metals: With Diagram | Metallurgy However, some metals like copper and nickel show complete solid solubility from 100% copper to 100% nickel, i.e., they are soluble in each other in the solid state in any proportion to give a series of solid solutions (having different proportions of metals), but with the same single FCC crystal structure. These are called extended solid solutions.

Phase Diagram for Cu-Ni Phase Diagram for Cu-Ni. Move the mouse over the phase diagram to view temperature and composition at any point. View micrographs for the Cu-Ni system. List all systems with phase diagrams. 2004-2022 University of Cambridge. Except where otherwise noted, content is licensed under a

Copper Nickel | PDF | Phase (Matter) | Phase Diagram A section of the copper-nickel phase diagram is contained here. Both the compositions and the phase amounts of each constituent will be determined at point B. The determination of phase compositions in a single phase, is just how much of each phase is present at a given temperature. In figure 1 at point A, the alpha region is the only phase ...

PDF Copper-Nickel Alloys: Properties, Processing, Applications The age-hardenable copper-nickel-silicon alloys with 1.0 to 4.5% Ni and 0.2 to 0.6% Be are not dealt with here. In European standards, these alloys are assigned to 'low-alloyed copper alloys' (see R 13388 and relevant product standards). Figure 1. (DKI A 4049) Cu-Ni equilibrium diagram

Mechanical Properties of Intermetallic Compounds ... - NIST Mechanical Properties of Intermetallic Compounds Formed Between Tin (Solder) and Copper or Nickel. Hardness as a function of temperature for Cu 6 Sn 5, Cu 3 Sn, and Ni 3 Sn 4. Toughness as a function of temperature for Cu 6 Sn 5, Cu 3 Sn, and Ni 3 Sn 4. Elastic moduli, thermal expansion coefficient, resistivity, heat capacity, density, thermal ...

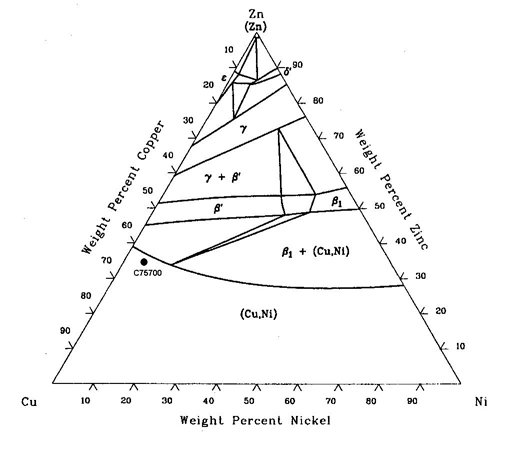

Cu (Copper) Ternary Alloy Phase Diagrams | Alloy Phase ... Abstract This article is a compilation of ternary alloy phase diagrams for which copper (Cu) is the first-named element in the ternary system. The other elements are Fe, Mn, Ni, Pb, S, Sb, Si, Sn, Ti and Zn. The diagrams are presented with element compositions in weight percent.

Pyrometallurgy of copper-nickel-iron sulphide ores: the ... Not obvious in these plots but evident in the copper-nickel phase diagram is a tendency to immiscibility in the fcc phase at low temperatures. This contributes to a further transformation at 750 K, in which the amount of copper combined with sulphur as digenite sharply declines, whereas that of nickel and iron combined with sulphur in ...

MECN 2010: Introduction to Copper Nickel Phase Diagram ... Introduction to the Cu-Ni phase diagram relating to the use of the Lever Rule for determining composition and phase weight percentages.

PDF Chapter 9: Phase Diagrams - Florida International University Phase Diagrams: composition of phases • Rule 2: If we know T and Co, then we know:--the composition of each phase. • Examples: TA A 35 Co 32 CL At TA = 1320°C: Only Liquid ( L) CL = C o ( = 35 wt% Ni) At TB = 1250°C: Both α and L CL = Cliquidus ( = 32 wt% Ni here) Cα = Csolidus ( = 43 wt% Ni here) At TD = 1190°C: Only Solid ( α)

Cu-Fe-Ni (Copper-Iron-Nickel) - Journal of Phase ... The Cu-Ni phase diagram [ 2007Tur] depicts a continuous fcc solid solution between Cu and Ni. The solid solution breaks into Cu-rich and Ni-rich fcc phases at low temperatures. The Fe-Ni phase diagram [ 1991Swa] is characterized by a very narrow solidification range, with a peritectic reaction between (δFe) and liquid yielding (γFe).

![a) Binary Cu-Al phase diagram modified from Ref. [9, 15] and ...](https://www.researchgate.net/profile/Dharmendra-Chalasani/publication/349066585/figure/download/fig1/AS:989518450683905@1612930991254/a-Binary-Cu-Al-phase-diagram-modified-from-Ref-9-15-and-b-Cu-Al-Ni-Fe-phase.png)

![Cu-Ni phase diagram [2]. | Download Scientific Diagram](https://www.researchgate.net/profile/Andras-Kovacs-5/publication/321224714/figure/fig1/AS:631621728337962@1527601763764/Cu-Ni-phase-diagram-2.png)

0 Response to "38 nickel copper phase diagram"

Post a Comment