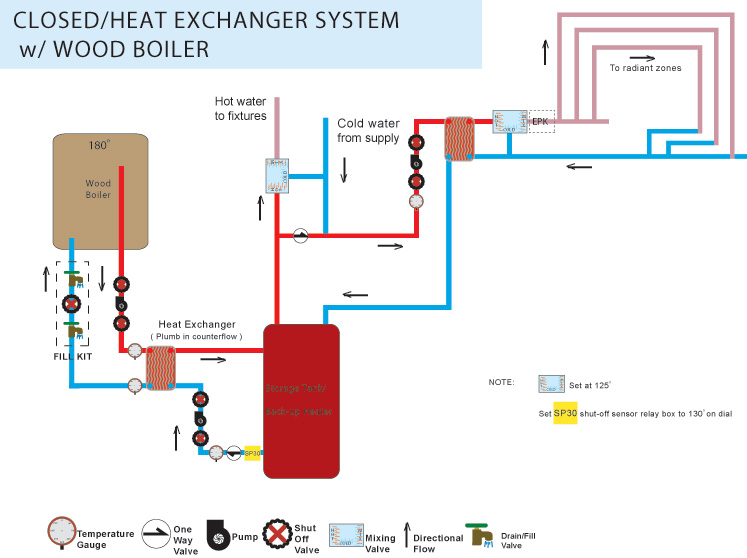

42 closed loop heating system diagram

24.2.2012 · Disadvantages of Closed Loop Control System. Disadvantages of a closed-loop control systems include: They are costlier. They are complicated to design. Required more maintenance. Feedback leads to an oscillatory response. Overall gain is reduced due to the presence of feedback. Stability is the major problem and more care is needed to design a ...

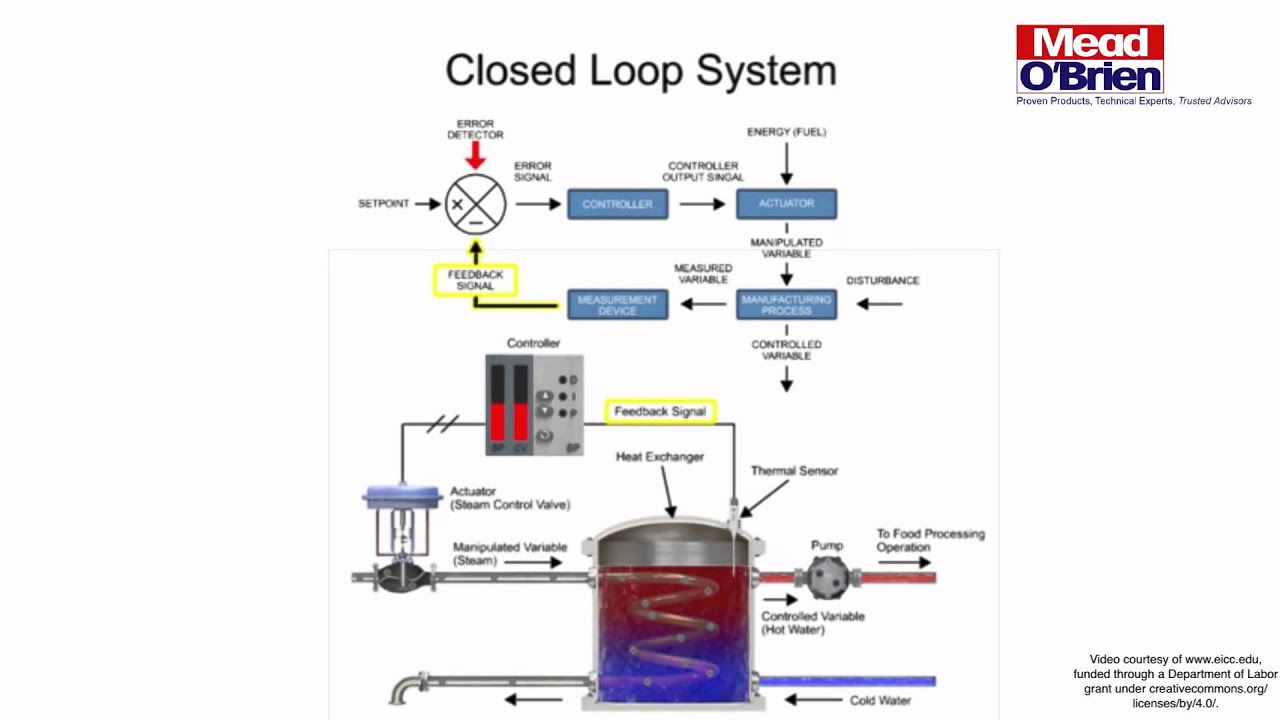

To overcome the limitations of the open-loop controller, control theory introduces feedback.A closed-loop controller uses feedback to control states or outputs of a dynamical system.Its name comes from the information path in the system: process inputs (e.g., voltage applied to an electric motor) have an effect on the process outputs (e.g., speed or torque of the motor), which is …

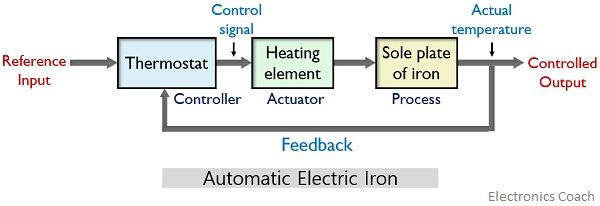

Examples of closed-loop control system. Here we will discuss the detailed operation of an automatic electric iron and a temperature control system. 1. Automatic Electric Iron. Consider an example of automatic electric iron which acts as a closed-loop system. The figure below represents the block diagram with major components: An automatic ...

Closed loop heating system diagram

Since glycol has a lower specific heat than water, higher concentrations of glycol in your closed loop water will reduce the heat carrying capacity of the system. Too much glycol will therefore increase energy costs as the system works harder to accomplish the desired heating or cooling.

Understanding the Basics of a Ground-Coupled (Closed Loop) Heat Pump Design: Part 1. Oct 9, 2019 10:00:00 AM. The ground source heat pump is a wonderful technology that will be vital in achieving energy efficiency goals this century. This technology isn't new, but it is beginning to become more accepted as a viable solution for large scale ...

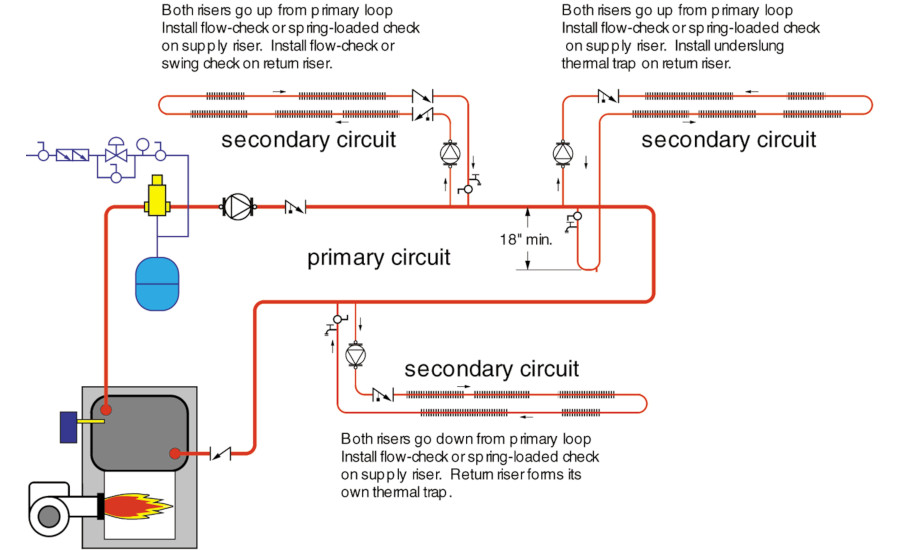

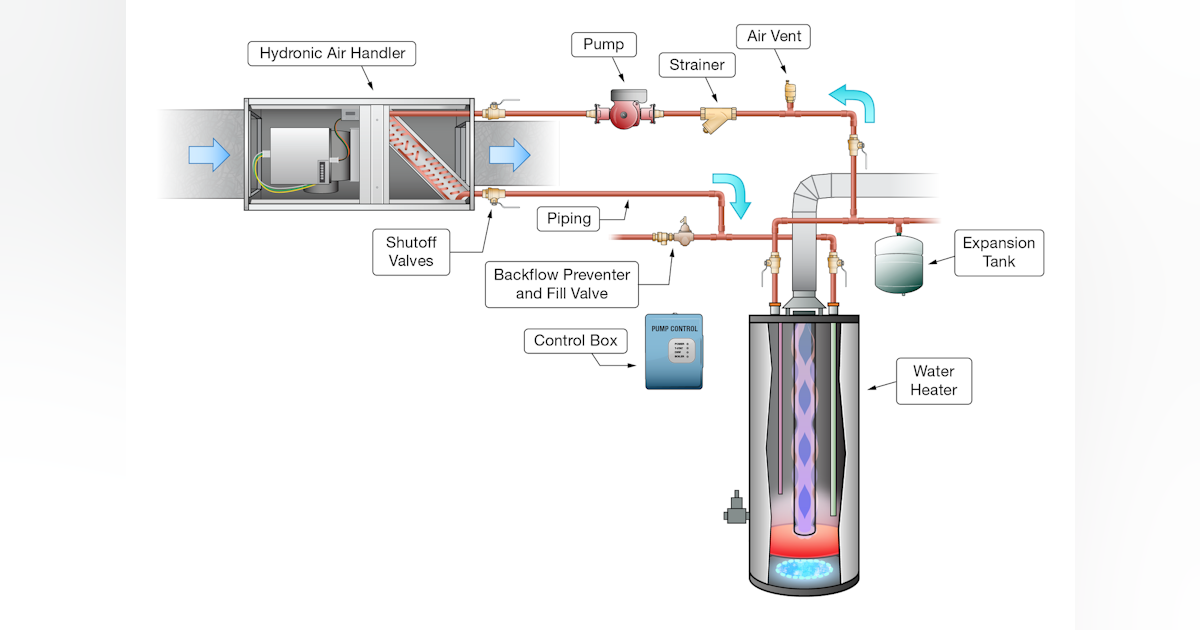

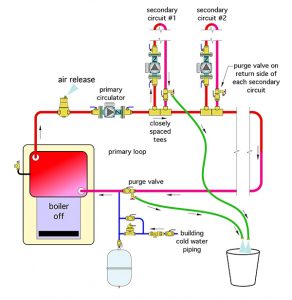

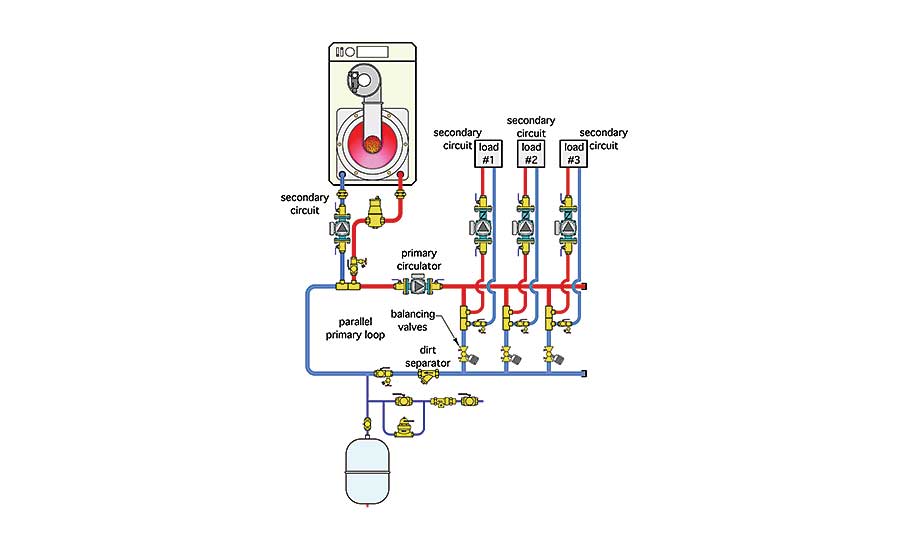

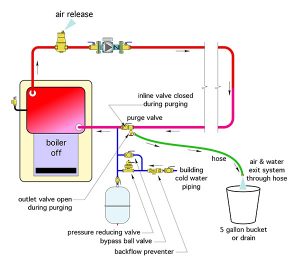

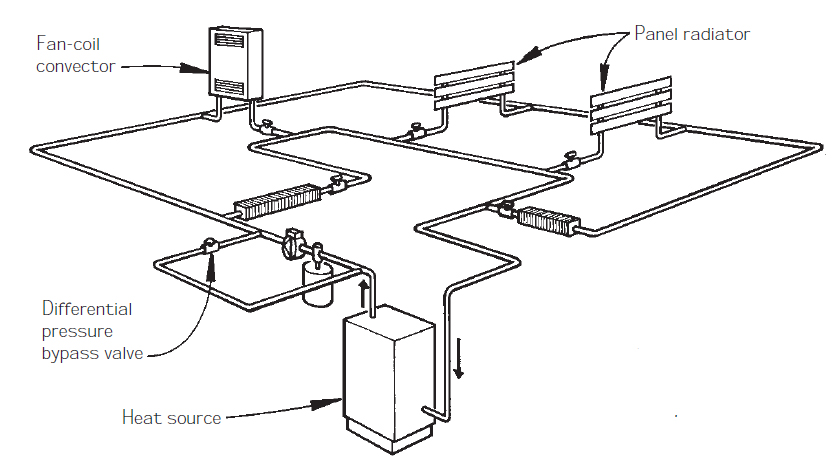

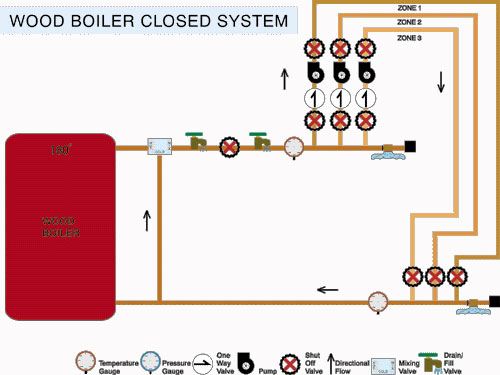

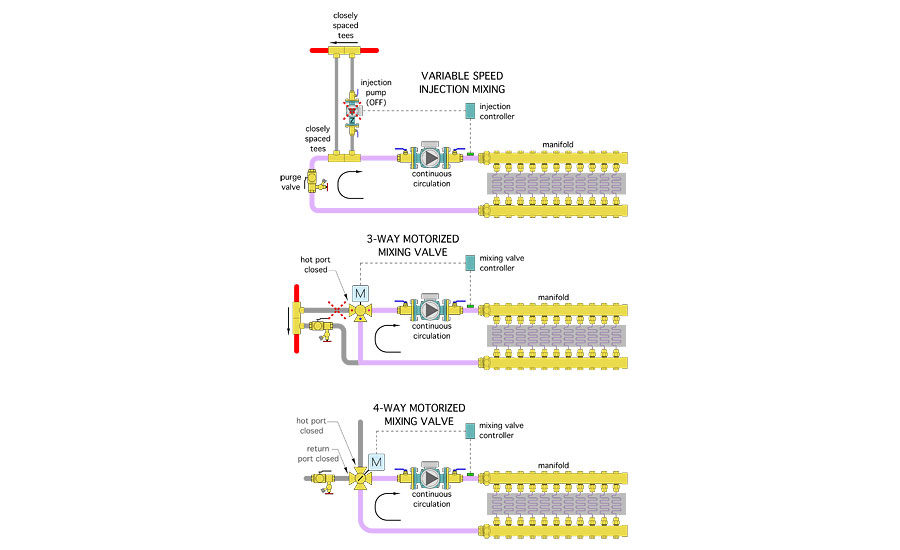

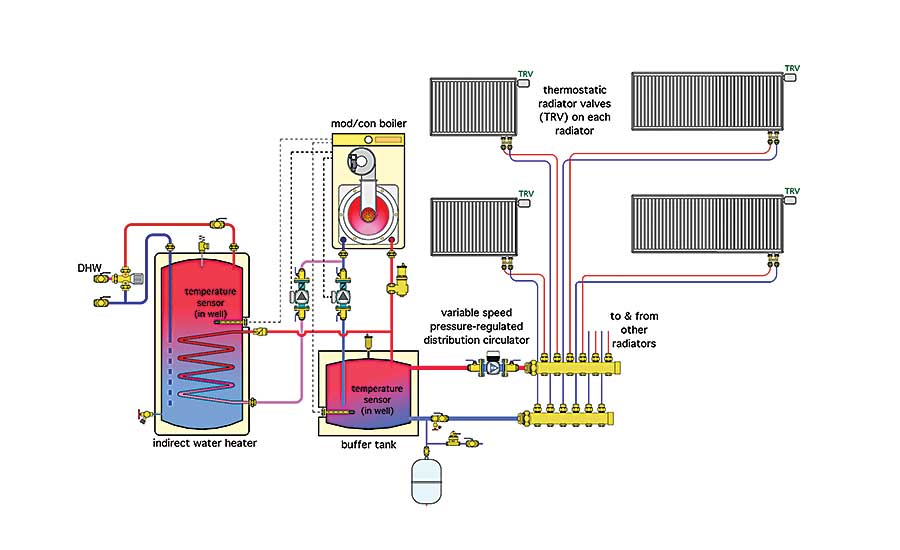

Primary Loop Piping is commonly used in boiler heating systems that run needing multiple temperatures or contstant temperature at the hydronic boiler is required. Primary Loop Piping allows non condensing boilers to maintain a heat level in the boiler high enough to allow the boiler to run at its most efficient state.

Closed loop heating system diagram.

Central heating systems come in generally three combinations. Open vented system using a hot water cylinder, a sealed system using a hot water cylinder and combination boiler systems. Open vented system layout This system is laid out as in the picture, with the main heating flow from the boiler being pumped into the motorised valve which chooses where the water goes depending on what the ...

24.1.2019 · The system input is also ineffective to disturbance produced in the toaster due to loss of addition of heat from surroundings. (b) Practical Closed Loop System: An automatic toaster with feedback is taken as an example of the practical closed loop control system. The block diagram is shown in Figure.

A heating system that is closed to the atmosphere and does not have a feed and expansion tank. How does a sealed system work? Sealed systems will use a pressurisation unit to provide automatic replacement of water losses and ensure minimum head requirements are maintained.

The central heating system is sealed (closed) and pressurised, usually to between 1 and 1.5 bar (cold). This pressure is the boiler pressure. When the system heats up, the water expands, taking up more space. The boiler pressure will rise a little, normally by up to half a bar.

Geothermal Heating and Cooling Systems In a geothermal heating and cooling system, the heat pump is connected to the building by a distribution system -- most commonly air ducts. And the heat pump is connected to the earth through a series of pipes called a "loop" which was previously described above. The system

The open-loop control system and closed-loop control system are the two types of control systems that you will learn in this article with the help of 4 practical examples from your daily life.. Before going to the details, you must understand what is a control system.

– Brine to water (indirect closed-loop heat exchanger, buried in the ground). • Heat pump dehumidifiers. Using the baseline scenario below, the potential financial (£), energy (kWh) and carbon savings (tonnes CO 2) have been calculated for comparison unless otherwise indicated: • Annual heating utilisation: 1,080 equivalent hours at full capacity. • Annual cooling utilisation (air and ...

Understanding central heating systems schematic of typical combi boiler and hot water system scientific diagram sealed open vented where the oil a solid fuel stove two zones domestic dhw cylinder nrg awareness explained centralized pipe section 8 y 602 2888 understand apply installation maintenance techniques block process control closed loop plastmax zonal circuits radiator advice sment ...

Sealed system with filling loop. Before you begin to fill the central heating system, make sure all the radiator bleed valves and drain cocks are closed. Open the valve on the filling loop, when the pressure reaches 1.5bar close the valve on the filling loop. As the radiators fill with water, air will become trapped at the top of the radiators. Open the radiator bleed valves one at a time ...

When compared to open-loop chiller systems, closed-loop cooling systems are space-efficient, as they do not require a separate heat exchanger unit. As a result, these machines will consume fewer square feet of floor space. The freed-up space can be used to store other equipment equally vital to industrial processes.

Closed loop HVAC systems explained - FAQs. Keeping closed loop heating systems corrosion free. Water-based HVAC systems transfer heat energy around a building by pumping water through pipework and associated components. Systems are either open to the air - in the case of cooling towers, or closed - in the case of sealed and pressurised designs.

www.houseneeds.com

17.7.2015 · In automatic control system or closed loop feedback system, we use a transducer at input side of the system to continuously monitor the temperature of the clothes inside the drier. The block diagram of the electric cloth drier is shown below.

The symbol used to represent a summing point in closed-loop systems block-diagram is that of a circle with two crossed lines as shown. The summing point can either add signals together in which a Plus ( + ) symbol is used showing the device to be a "summer" (used for positive feedback), or it can subtract signals from each other in which case a Minus ( − ) symbol is used showing that the ...

closed-loop control system: Feedback from the output to the input is missing in the open-loop control system. To obtain More accurate Control, the controlled variable should be fed back and compared with the reference input.

The closed-loop heating system has some advantages, such as overall system accuracy and ease of integration. Because this method can account for unexpected changes in the process, such as variations in ambient temperature or pressure, shifts in supplied voltage, or wind and air flow shifts, it gives the system the ability to manipulate the ...

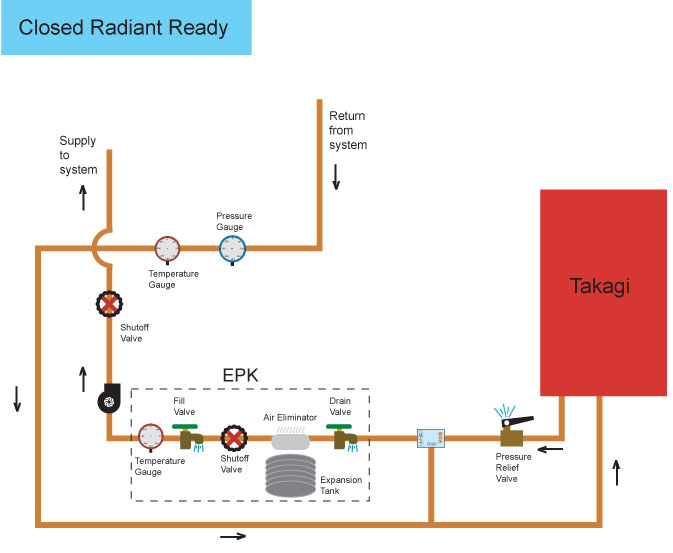

The Closed System This approach utilizes a dedicated heat source for the radiant floor. The fluid in a closed system is re-circulated around and around in a completely closed loop. There is no connec-tion whatsoever to the domestic water supply. The main advantage to this system lies in the fact that, being closed, anti-freeze instead of

Radiant heat plumbing diagram. Its available from several manufacturers with either an internal thermostatic element or an external actuator. Complete radiant heating system using a navien on demand boiler closed loop system. There is no connection whatsoever to the domestic water supply. Install a plumbing mechanical package pmp.

The block diagram of the closed-loop system is shown below. The basic elements of the closed-loop control system include error detector, controller, feedback elements & power plant. Closed-Loop Control System Block Diagram When the control system includes a feedback loop, then the systems are known as feedback control systems.

Closed loop heat pumps utilize a system in which there is a heat pump in each zone of a building. The heat extractors of all these units are connected together by a closed loop of circulating water. System Components. The principal components of the system are several small self-contained heat pump units which have the capability of reversing ...

Thermal System Case Study Kevin Craig 1 Thermal System Closed-Loop Temperature Control •aluminum plate •thin-film resistive heater •ceramic insulation •conduction and convection heat transfer •AD590 temperature sensor •microcontroller •on-off closed-loop control with relay •support analog electronics

A closed heating system does not need a high level header tank outside the insultaion layer. This has the following advantages; • The safety- and expansion line to the highest point in the system, as well as the overflow line are becoming redundant. • No ball (float) valve in header tank which can seize shut. Air in a closed heating systems Air in cealed systems should be removed at all ...

To protect the unit, you must consider an open or closed water heater system. An open water heater system is when water that increased its volume and pressure due to the heating freely goes from the storage tank into the cold water supply line and eventually into the municipal water system if the pressure is high enough.

International Course on GEOTHERMAL HEAT PUMPS _____ _____ 2 western and eastern states from North Dakota to Florida. Today there are an esti-mated 500,000 units (12 kW equivalent) installed with 50,000 installed annually. Of these 46% are vertical closed loop, 38% horizontal closed loop and 15% open loop systems (Lund, 2001). Projections for the

recirculating closed loop or a once-thru system using water from a well, a pond, or a stream. Water for closed-loop heat pumps is usually circulated at 2.25 to 3.00 gpm per ton of unit cooling capacity. A once-thru groundwater heat pump can operate with a lower water flow, but the same range is still recommended.

Combi system. This diagram illustrates how simple the heating system connected to a combi boiler is. No external pump, no tanks, no external expansion vessel, no motorised valves and in many cases item 6 is not needed either. (An automatic bypass valve is fitted inside most combi boilers by the manufacturer these days.)

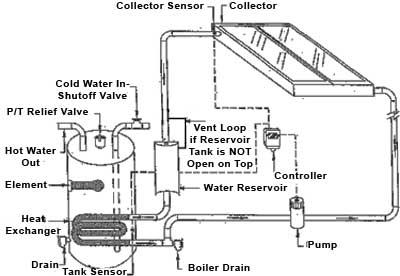

Two PV Pumped Closed Loop Solar Water Heating Systems. This page covers two closed loop solar water heating systems that use a PV powered pump to circulate the working fluid. Both systems have been in operation for quite a while and work well. The first is Doug's own system, and the 2nd is a system that Doug helped friend Bob install.

The fluid in a closed system is re-circulated around and around in a completely closed loop. There is no connection whatsoever to the domestic water supply. The main advantage to this system lies in the fact that, being closed, anti-freeze instead of water can be used as the heat transfer medium. The percentage of anti-freeze (Propylene Glycol) is determined by the type of heat source (on ...

in a closed loop system • What produces head loss? Friction of the water rubbing against the pipe as it flows through the system. • 1 PSI of pressure drop = 2.31 feet of head • Does height of the building influence head loss? No • Why?It's a circulator, not a pump. It's a closed loop system and the weight of the

systems for cold climates. This article concentrates on the as-sembly and installation of closed loop anti-freeze SDHW systems, hereinafter referred to as closed loop sys-tems. "Installation Basics for SDHW Systems" in HP94 covered aspects of installation common to most solar water heating installations, such as collector location and mounting,

System Diagrams Radiant Heat Multi Zone In-Floor 71 73 75 80 86 102 76 67 65 Forced Air vs. Radiant In-Floor Insulation Closed-cell Polystyrene Thermal Insulation OUT IN Greenhouse Heating Options Radiant PEX piping under the table Forced Air Return Supply When using mesh style tables - PEX piping must be protected from UV rays. 4 mil. black ...

CLOSED-LOOP SYSTEM Definition: The closed-loop system is defined as Feedback from the output to the input is missing in the open-loop control system. To obtain More accurate Control, the controlled variable should be fed back and compared with the reference input.

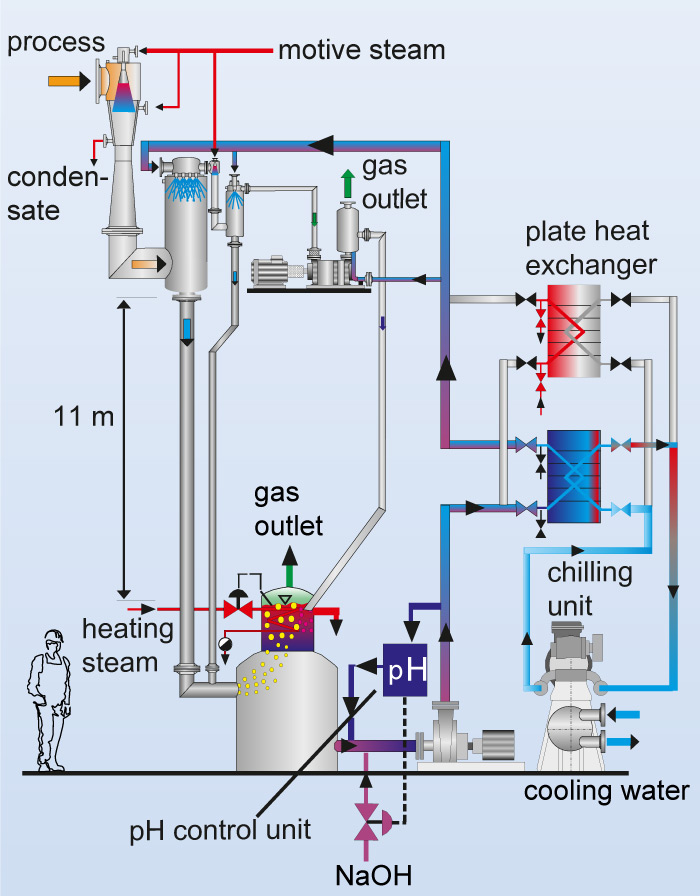

![9 Residential heating system (closed loop) [18] | Download ...](https://www.researchgate.net/profile/Amlan-Basu-2/publication/303960009/figure/fig7/AS:372898276626433@1465917285264/Residential-heating-system-closed-loop-18.png)

0 Response to "42 closed loop heating system diagram"

Post a Comment