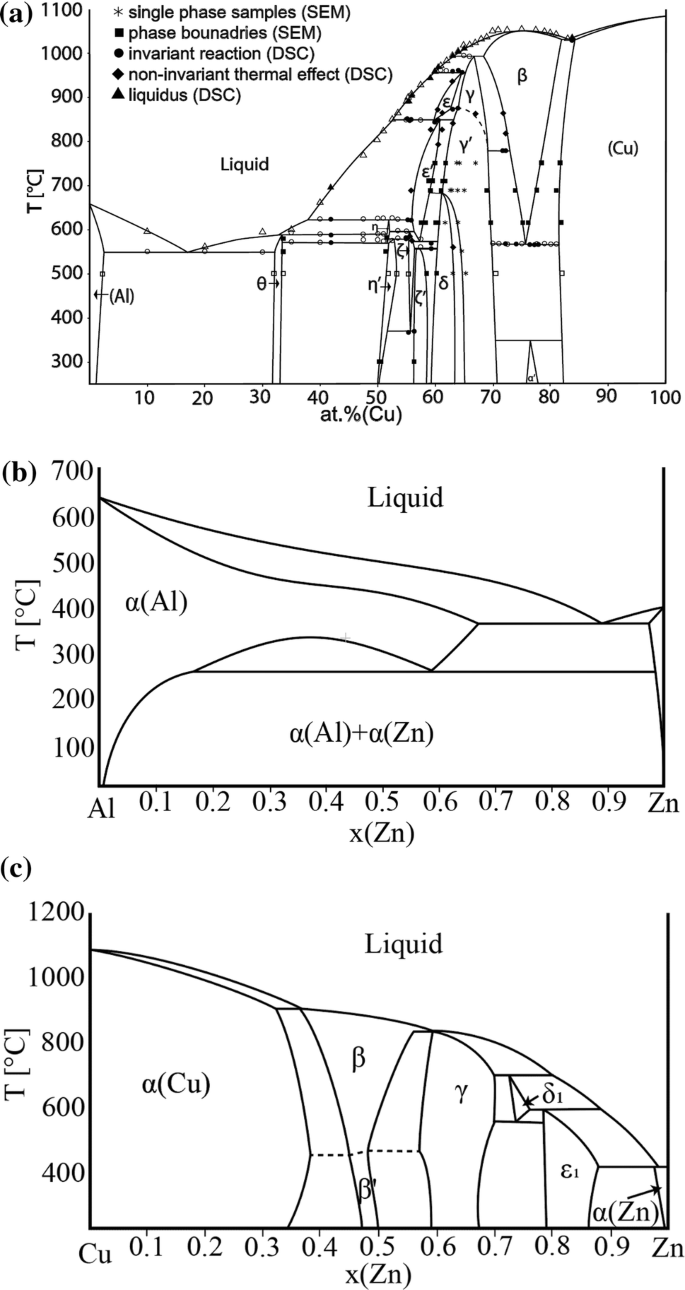

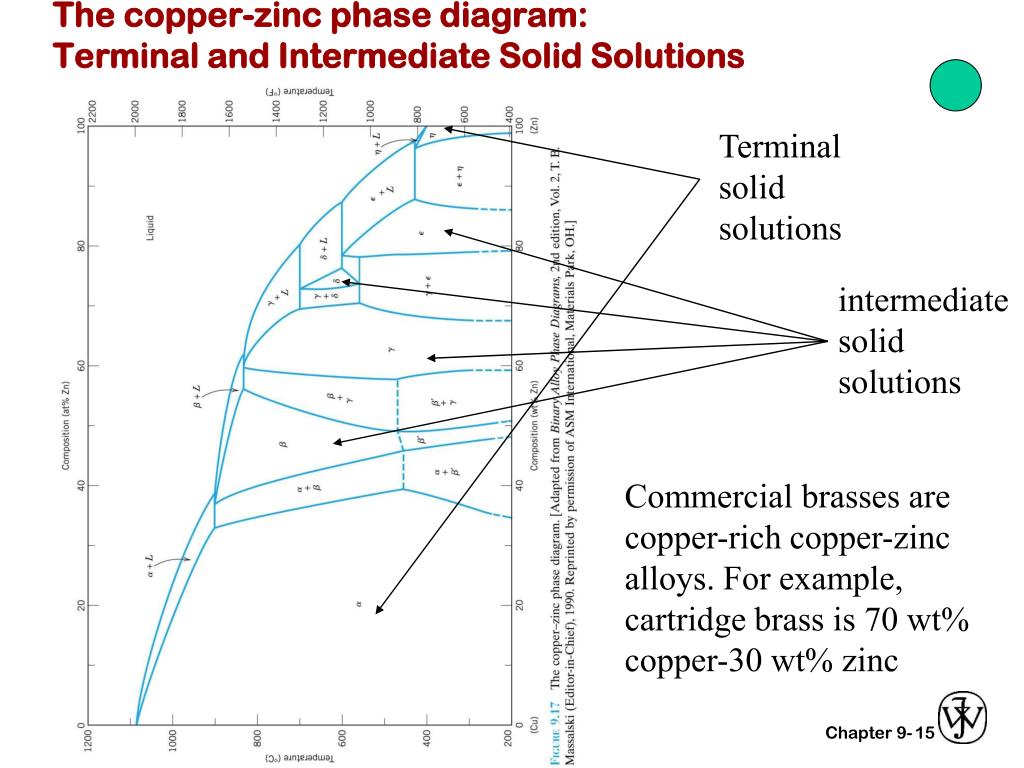

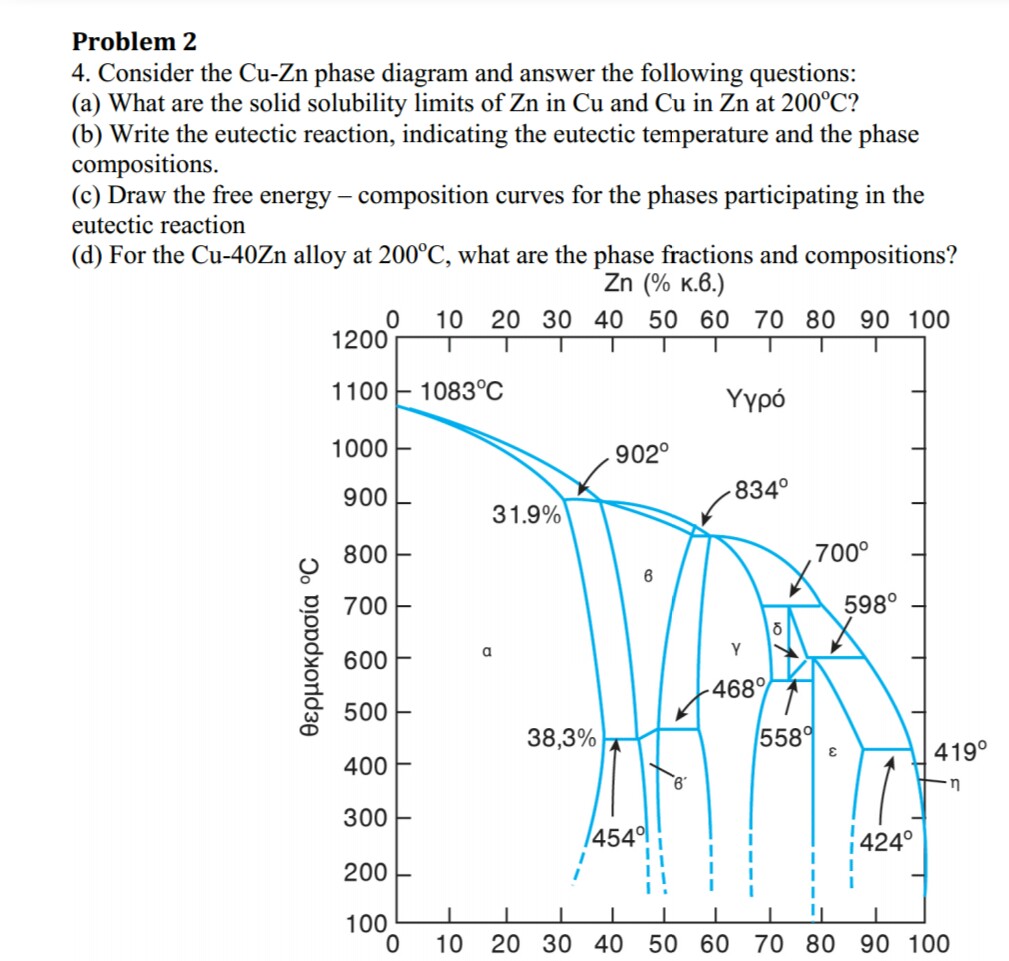

39 cu-zn phase diagram

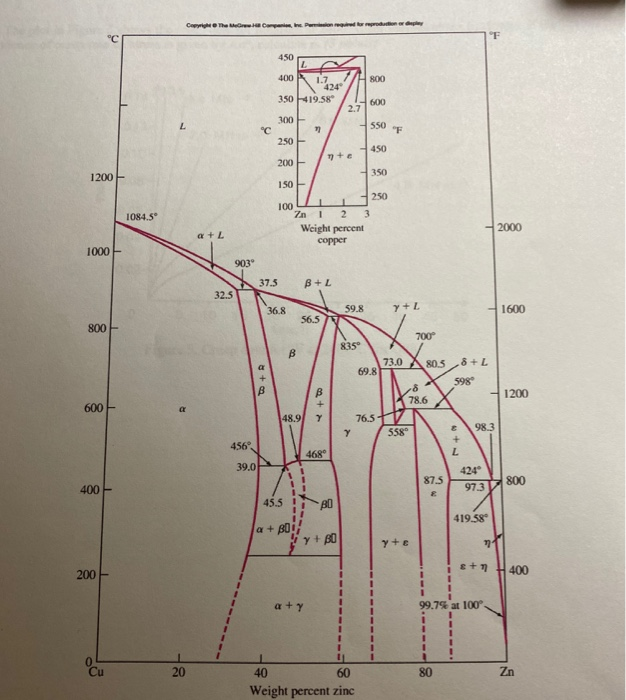

Cartridge brass (70Cu-30Zn) is the most widely used brass. The important points in Cu-Zn phase diagram from metallurgical point of view are maximum solubility ...

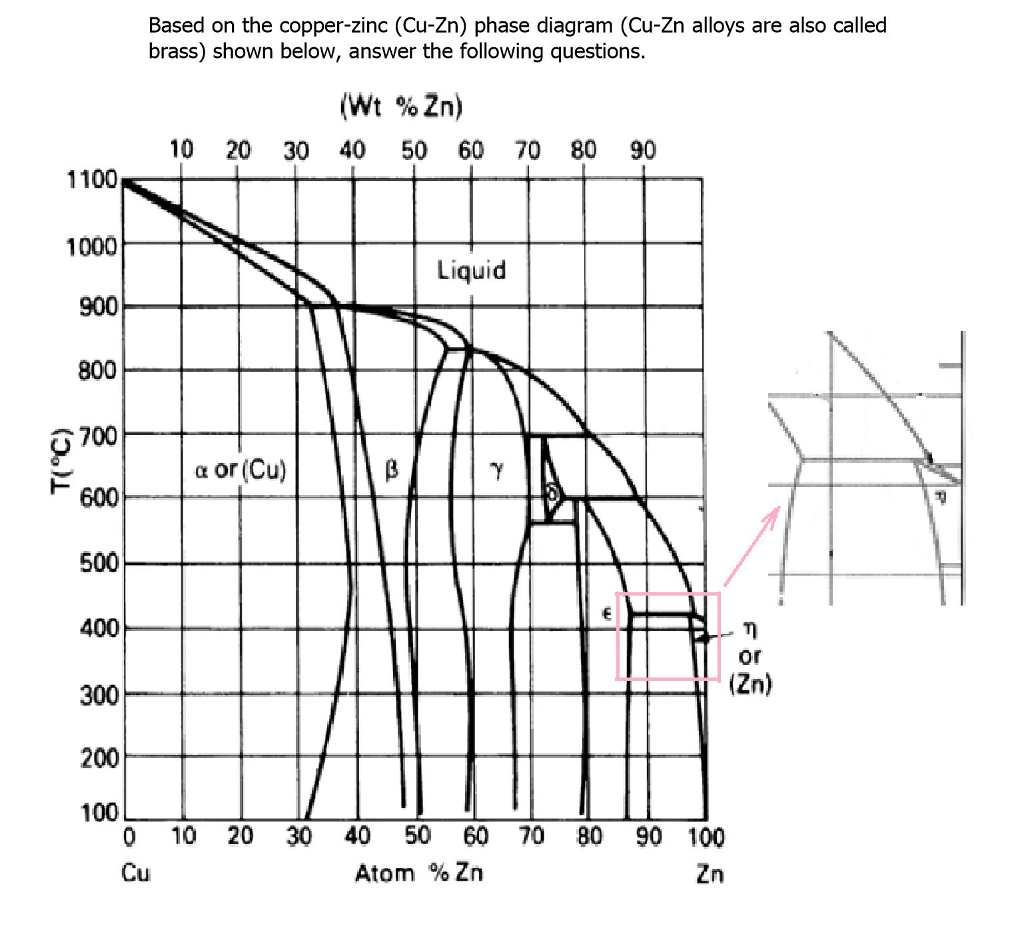

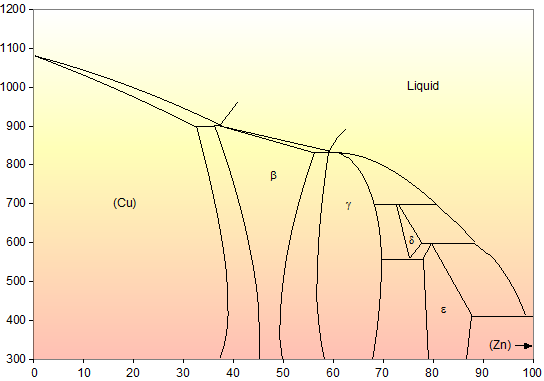

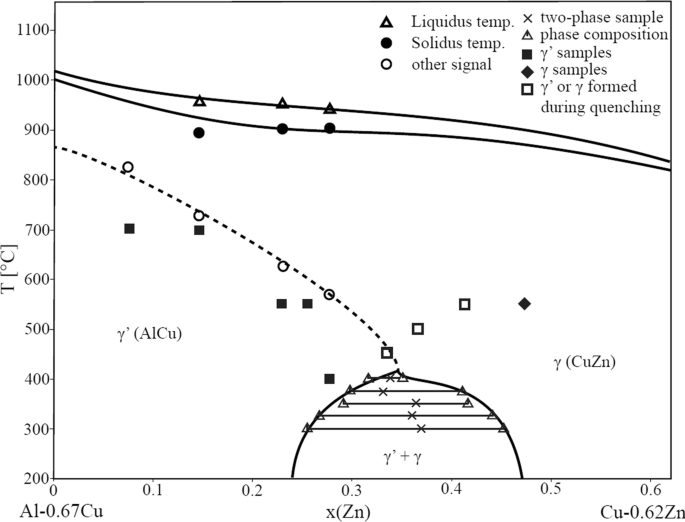

Figure 2 illustrates the binary phase diagram for the Cu/Zn system of brass (for alloys with compositions of 0 Á/50 wt.% Zn). The diagram provides a 'map' ...

The phase α and β phases are represented by light (needles or plates) and dark regions, respectively. The α phase (light region) represents a solid solution of ...

Cu-zn phase diagram

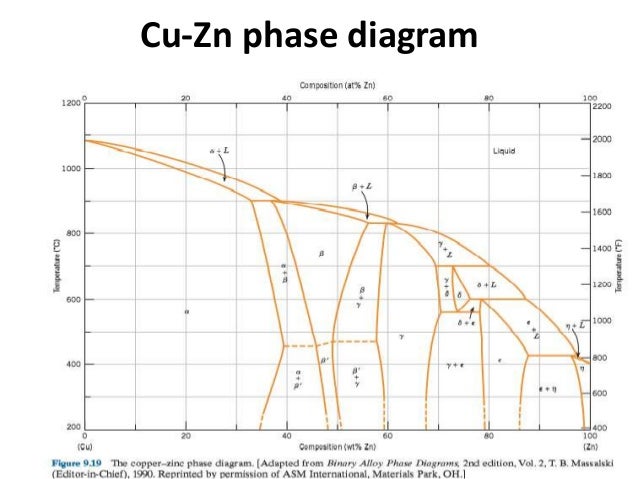

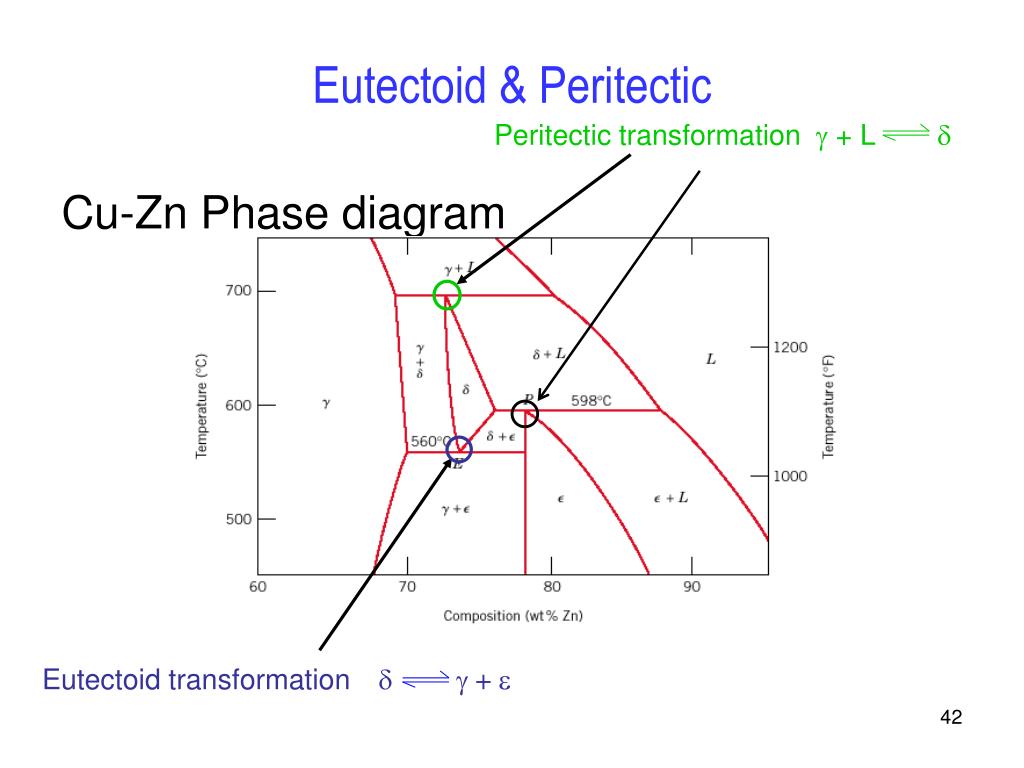

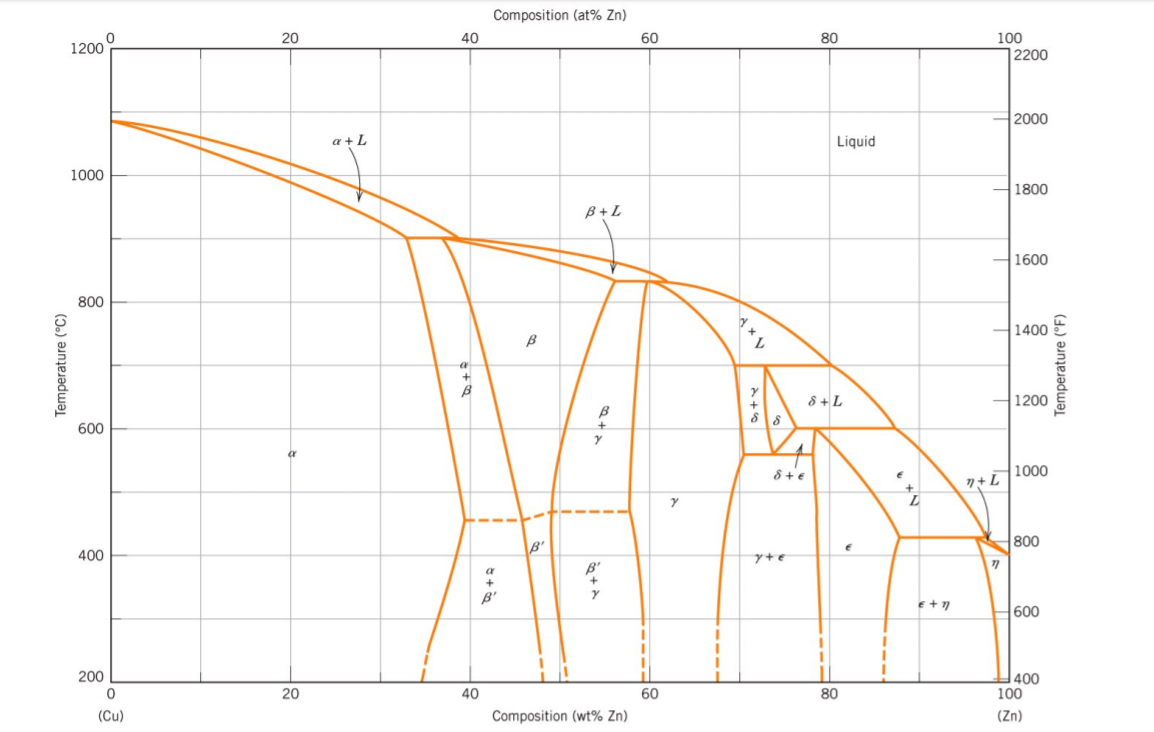

The copper-zinc phase diagram: ... Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc.

This problem asks that we cite the phase or phases present for several alloys at specified temperatures. (a) That portion of the Cu-Zn phase diagram (Figure 9.19) that pertains to this problem is shown below; the point labeled “A” represents the 90 …

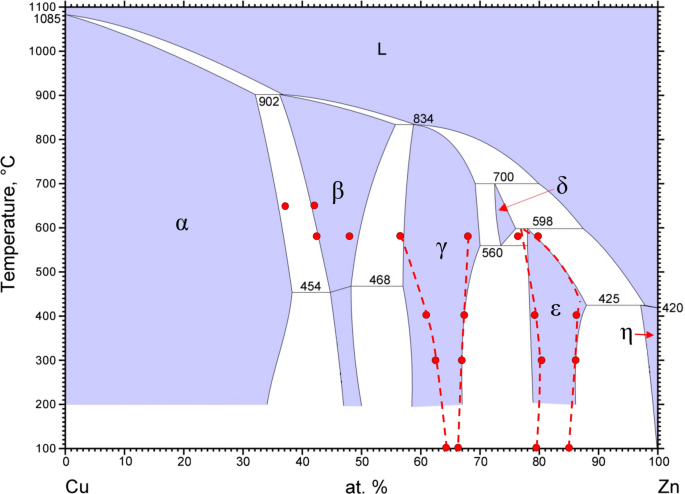

Fig. 1 Cu-Zn binary phase diagram as reported in the ASM Alloy Phase Diagrams Database[17] based on the assessment of Miodownik.[14] The red dots and dashed lines represent suggested changes to the phase boundaries based on experimental results obtained from the present study J. Phase Equilib. Diffus. (2020) 41:642–653 643 123

Cu-zn phase diagram.

This problem asks that we determine the phase mass fractions for the alloys and temperatures in Problem 9.8. (a) From Problem 9.8a, ε and η phases are present for a 90 wt% Zn-10 wt% Cu alloy at 400 °C, as represented in the portion of the Cu-Zn phase diagram shown below (at point A).

金属やセラミックスの状態図、エンリンガム図などの情報を提供しています。 一部、不確かなものもありますので、自己 ...

**[Gold Rundown:](http://i.imgur.com/FjcyE.png)** Valence: +1 Crystal Structure: [FCC](http://en.wikipedia.org/wiki/Cubic_crystal_system#Cubic_space_groups) Density: 19.32 g/cc Melting Point: 1064^o C Thermal Conductivity: 317 W/m-K Elastic Modulus: 78 GPa Coefficient of Thermal Expansion: 13.93 microns/^o C Electrical Resistivity: 2.35 micro Ohms-cm Cost: $44,542/kg as of January 12, 2011 at 11:30pm Eastern Time Gold has the highest electronegativity of all metals, 2.4 Paulings. All o...

Download scientific diagram | Equilibrium Cu-Zn phase diagram [5] from publication: Comparison of the Structure of CuZn40MnAl Alloy Casted into Sand and Metal Moulds | CuZn brasses are used for ...

Move the mouse over the phase diagram to view temperature and composition at any point. View micrographs for the Cu-Zn system. List all systems with phase diagrams.

**Copper Continued!** **Ductility:** Copper is FCC, as discribed above. The classic slip plane for this system is the {111}<110> slip system, which I bet no-one here knows, but you will know after you look at [this picture](http://i.imgur.com/2EkoK.png). Essentially, individual copper atoms will slide across other copper atoms in a very specific direction in the crystal structure (follow the arrows). In the diagram, the burgers vectors b2 and b3 are longer than the path traveled with the ...

**Aluminum Mechanical Properties:** As stated earlier, Al is an FCC metal. The critical resolved shear stress is only 1 MPa. That might not mean much all by itself, so first I'll quickly explain what the critical resolved shear stress is. Imagine a single crystal of aluminum in the shape of a cylinder. If you were to put a load P on the long axis of the cylinder, the crystal would deform but it WOULDN'T just squish the cylinder to make it fatter. [Diagram of load P](http://mmd.sdsmt.edu/yieldpoi...

I am pouring a small casting of scrap brass and I am having some trouble capturing finer detail. This lead me to explore factors that could help. I know a higher pour temp would reduce viscosity and I have seen papers that going from 5% zinc to 10% reduces viscosity. I know zinc in ZAMAC is used in thin wall and complex die casting. I had the idea to just keep increasing zinc content to get where I wanted to be. I can't really find any information on brass or even generic copper/zinc alloy ...

Pourbaix diagram One certain class of phase diagrams is displayed by the equilibrium electrical potential plotted against the pH, when some of the reactants have chemical activities that vary with pH. For instance if H + is part of the electrode reaction, then under dilute approximation, a H+ ∼ c H+. The pH of the electrolyte is defined as the negative of the natural log of the H+ ion ...

Hey guys, I am working on a project where I need to classify microstructure phases of different alloy system using deeplearning. I am using images from website [https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic](https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic) But I am not expert enough to know all the phases of all the alloy system. I looked into Google and phase diagram of different alloy system but can't correlate with shapes of phases in images with the phas...

24.11.2021 · This could be explained according to the phase rule and phase diagram between Cu and Zn. Cu-Zn was an important binary alloy system. In the interested temperature ranges from 300 to 1500 K, there were eight phases: liquid, Cu, β, β′, γ, δ, ϵ, and Zn phases, as shown in Figure 7. A new description of the liquid phase and a simplified description of the body …

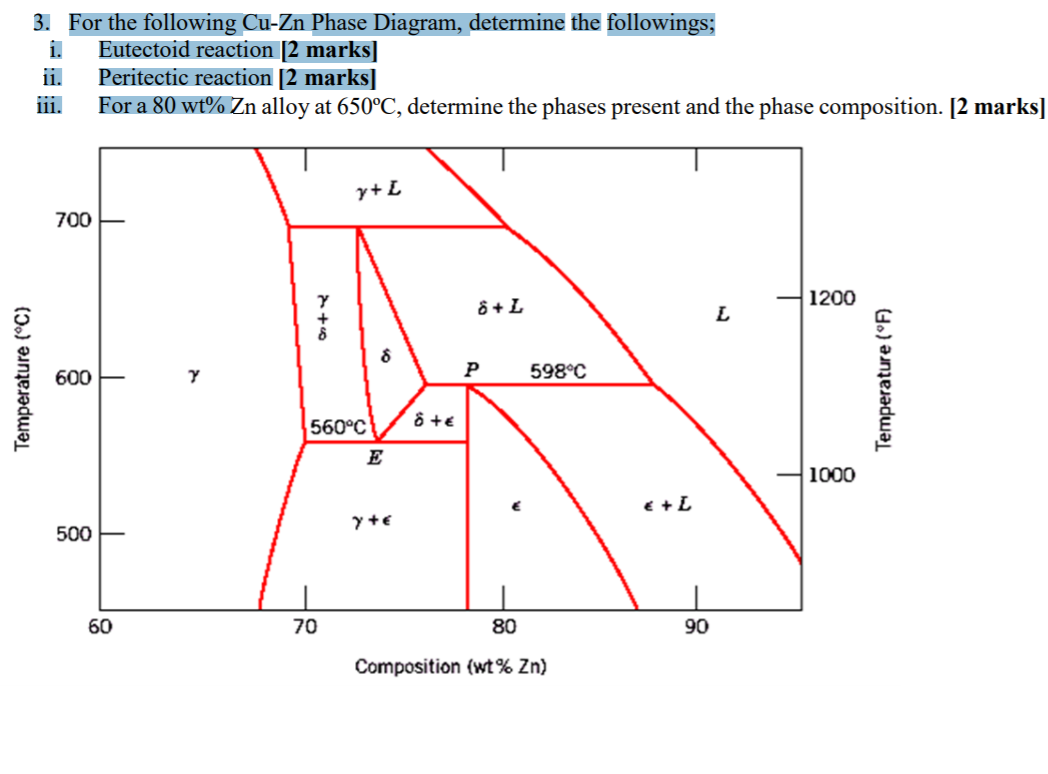

That portion of the Cu-Zn phase diagram (Figure 9.19) that pertains to this problem is shown below; the point labeled “E” represents the 53 wt% Zn-47 wt% Cu composition at 500°C. As may be noted, point E lies within the β + γ phase field. A tie line has been constructed at 500°C; its intersection with the β−β + γ phase boundary is at 49 wt% Zn, which corresponds to the …

**Germanium Rundown:** Ge is very similar to Si in several ways, however it is *much* less abundant on Earth and therefore global Ge production is only 70 tons/yr. Ge is a semiconductor with a 0.67 eV band gap that can be used to make microelectronic devices, fiber optic glasses, phosphors, infrared optics and catalysts. **Ge History in Semiconducting World:** On December 23, 1947 Brattain and Bardeen invented the world's first transistor. It was a "point contact" resistor that was created by...

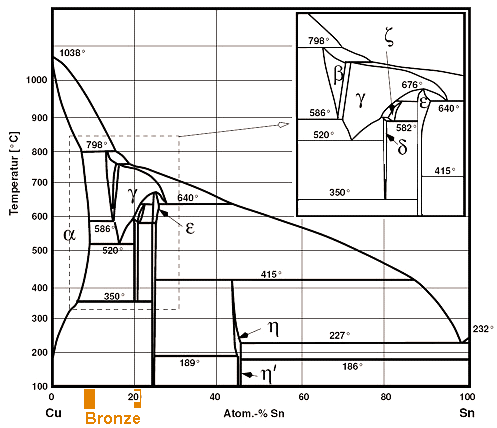

Shown below is the Mg-Pb phase diagram (Figure 9.20) and a vertical line constructed at a composition of 50 wt% Pb-50 wt% Mg. (a) Upon cooling from 700°C, the first solid phase forms at the temperature at which a vertical line at this composition intersects the L-(α + L) phase boundary--i.e., about 560°C; (b) The composition of this solid phase corresponds to the …

FSlead - FactSage Lead Alloy Phase Diagrams (161) Click on a system to display the phase diagram.

what a phase diagram is; how to read it; how phases change on heating and cooling; the resulting microstructures. When you have worked through this unit you should be able to do the following: (1) Interpret the equilibrium phases at any point on binary phase diagrams. (2) Predict the microstructures which may result from simple processing histories relating to solidification …

Metals including Ag, Cu, Zn, Cd, and Hg can be used as indicator electrodes for their aqueous ions (most metals cannot be used, as necessary equilibria at a metal surface are not established). Junction Potential Junction potential: A small voltage difference (a few mV) that develops at the interface of two dissimilar electrolyte solutions are in contact with one another. The junction …

The copper - zinc phase diagram is a bit simpler than the copper - tin phase diagram but still complex enough. There are all kinds of brass' but typically we are at the copper-rich side.

Download scientific diagram | The Cu Zn phase diagram that is shown in many compilations of phase diagrams. The intermetallic phases β′ γ and ε do not ...

by W Gierlotka · 2008 · Cited by 31 — Cu–Zn is an important binary alloy system. In the interested temperature range from 300 to 1500 K, there are eight phases, liquid, Cu, β, β′, γ, δ, ϵ, ...

The illustration below is the Cu-Zn phase diagram (Figure 10.19). A vertical line at a composition of 64 wt% Zn-36 wt% Cu has been drawn, and, in addition, horizontal arrows at the four temperatures called for in the problem statement (i.e., 900°C, 820°C, 750°C, and 600°C).

![Phase diagram of the copper–zinc system [17]. | Download ...](https://www.researchgate.net/profile/Efthimia-Kaprara/publication/257647664/figure/fig1/AS:392543461232654@1470601062900/Phase-diagram-of-the-copper-zinc-system-17.png)

![Chapter 9] Use the partial phase diagram below to determine ...](https://img.homeworklib.com/images/6cc752ea-06cd-4406-952e-8ec36eded450.png?x-oss-process=image/resize,w_560)

![Equilibrium Cu-Zn phase diagram [5] | Download Scientific Diagram](https://www.researchgate.net/profile/Pavel-Kejzlar/publication/316598481/figure/fig2/AS:616354306588689@1523961726879/Equilibrium-Cu-Zn-phase-diagram-5.png)

![2. The equilibrium Cu-Zn phase diagram. [61] | Download ...](https://www.researchgate.net/profile/Zhou-Peng-7/publication/322748528/figure/fig4/AS:587563039461383@1517097353986/The-equilibrium-Cu-Zn-phase-diagram-61.png)

0 Response to "39 cu-zn phase diagram"

Post a Comment