39 continuous cooling transformation diagram

So! Last time, the full chapter for the week was about 4.6k worth of words, a reminder of old days when chapters would run long... Anyways, my new writing schedule is working out where I get more time to work on these chapters and, uh, they're getting long again. So, enjoy this 5.2k word chapter! ___ Red skies loomed over the camp, watching the tinkerers and minions run around the campsite with a fatal interest. The creatures hurried, trying to build a barricade, chopping down nearby trees and c...

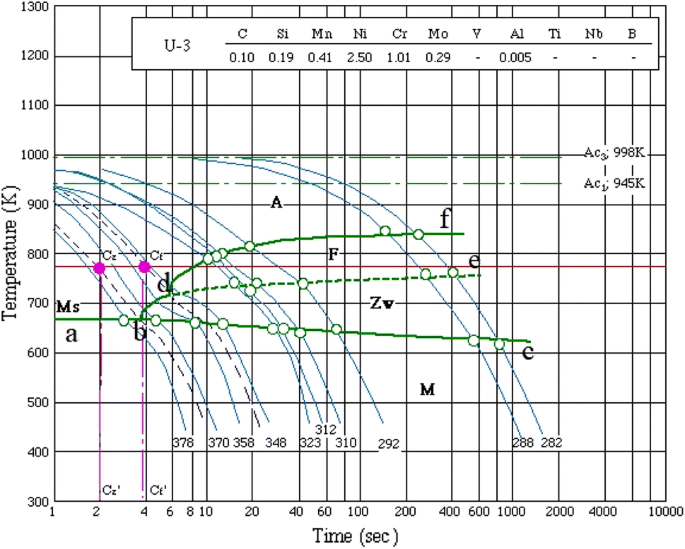

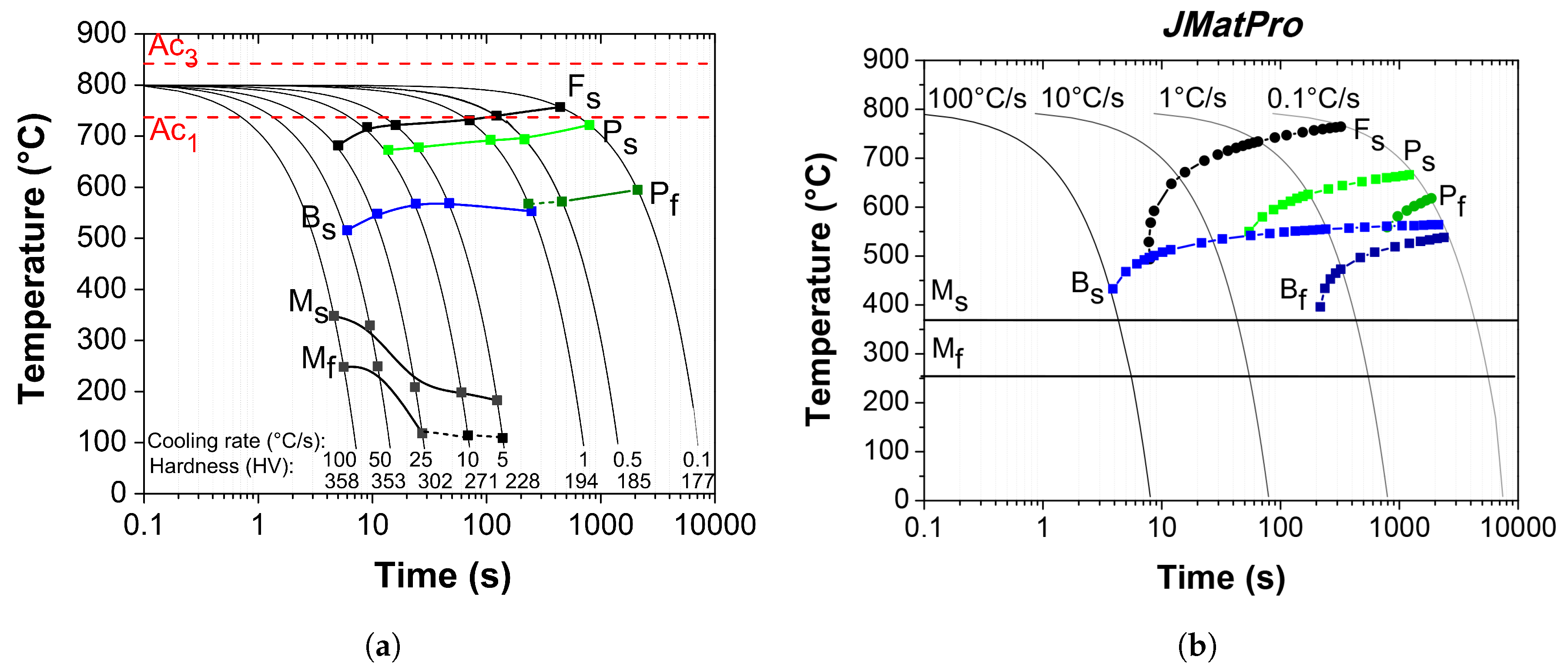

A continuous-cooling transformation diagram was produced using JMatPro material performance simulation software (Sente Software Ltd., Guildford, UK). The temperature range of ferrite formation was determined using this diagram. It provided a basis for the selection of temperature ranges in the subsequent study of the kinetics of ferrite formation.

JMatPro software was also used for the prediction of continuous cooling transformation (CCT) diagrams for austenite decomposition as well as hardness and microstructure predictions. To calculate a CCT diagram using JMatPro software, except the chemical composition, the quenching temperature and the ASTM grain size should be given as an input.

Continuous cooling transformation diagram

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

My God, we are at chapter 30? That's insane! Well, strap in because we have a LOT of words for this chapter, about 4.2k, or close to 16ish pages. I hope you enjoy! ___ As it turned out, things could get worse for the half-elf as he found himself balancing on a branch from the tallest tree within the forest around the camp. Swaying yellow and green leaves and other brown branches were Reynauld's only friends here; even the squirrels wouldn't venture up here. By being so high, Reynauld saw down th...

This atlas is a collection of continuous cooling transformation diagrams applicable to low carbon low alloy weld metals. It will be of assistance to welding engineers, welding metallurgists, welding-consumables designers in industry. TABLE OF CONTENTS . chapter 1 | 1 pages Introduction .

Continuous cooling transformation diagram.

A continuous cooling phase diagram related to the cooling rate was established, which can further quantify and characterize the corresponding relationship between the cooling rate and the phase transformation mechanism, and guide the formulation of continuous cooling process for titanium alloy. MATERIALS AND METHODS

*Welcome to my G.I. Joe Rewind, where I’m going back to re-read the original G.I. Joe comics and hopefully spark some discussion on them.* Link to previous Rewinds: [#1](https://www.reddit.com/r/gijoe/comments/p12aji/g_i_joe_rewind_arah_marvel_1_jun_1982/) [#2]( https://www.reddit.com/r/gijoe/comments/p1p3vy/g_i_joe_rewind_arah_marvel_2_aug_1982/) [#3]( https://www.reddit.com/r/gijoe/comments/p2cuj5/g_i_joe_rewind_arah_marvel_3_sept_1982/) [#4](https://www.reddit.com/r/gijoe/comments/p2zrgc/g_i...

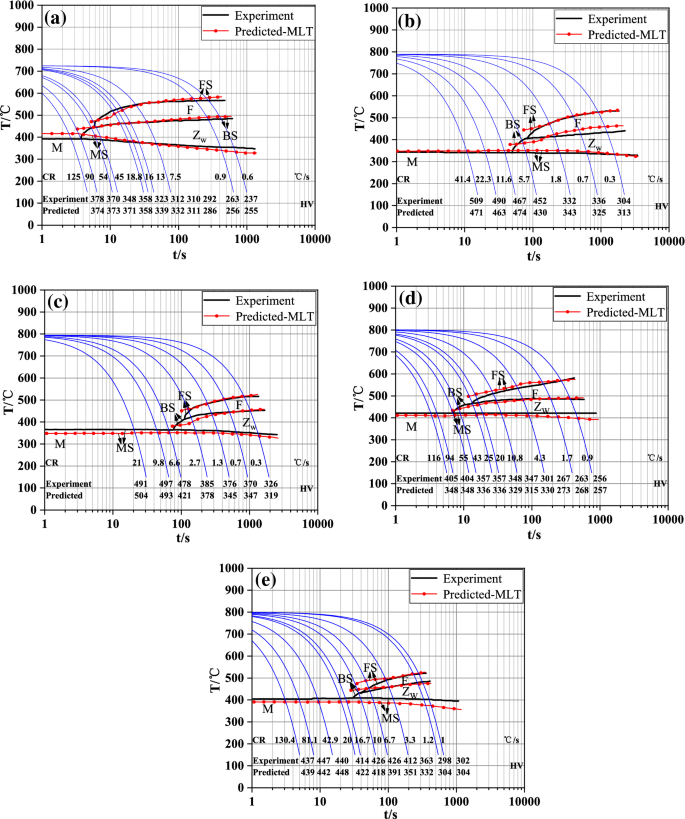

Subsequently, the predictive ability of the model is demonstrated by means of continuous cooling transformation diagrams, showing that experimentally observed characteristics such as critical cooling rates emerge naturally from the proposed microstructure model, instead of being enforced as heuristic transformation criteria.

Sadhana. Volume 46. All articles. Continuous cooling transformation diagram and mechanical properties in weld coarse-grain heat-affected zone of API X70 steel. AJIT KUMAR NAIK RAKESH ROSHAN KANWER SINGH ARORA NIKHIL SHAJAN SUBASH CHANDRA MISHRA. Volume 46 Published: 28 April 2021 Article ID 0088.

This in turn makes for distinct critical cooling rates, phase transformation and final hardness. So, to successfully model these materials, we need to incorporate the Continuous Cooling Transformation (CCT) diagram — a graph that reflects which types of phase changes will occur in a sheet metal part as it is cooled at different cooling rates.

Hi all, come on in! But also stay out until I observe you doing one or the other and force you into a definitive state. Just finished Season 3 of Dark? Congratulations on finishing what is arguably the most complex television gauntlet ever crafted! Let's all agree that Dark is one of the most confusing shows of all time, *perhaps* even to a fault. While the show gives you plenty of answers up front, it also holds back quite a few of them that are waiting to be found amongst the dirty details wh...

When I first heard about ATCOR, I didn't believe it. I figured it was a wildly unrealistic principle, and I couldn't find many resources about it to understand it. I thought this itself was very suspicious, since it was so "overpowered" if true, I would have expected people to have prepared detailed resources long ago to shout from the rooftops. However, I think I've finally just about managed to wrap my head around it for the most part, and now I feel like it could be surprisingly robust. I ...

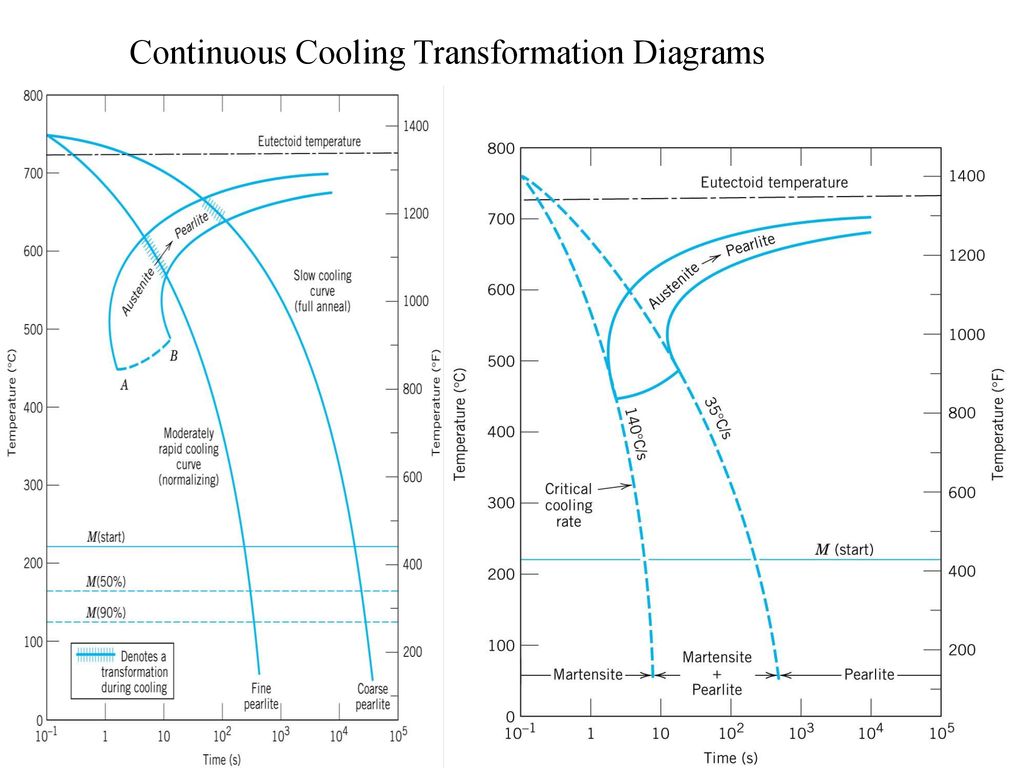

Hence, the so-called Continuous Cooling Transformation diagrams (CCT diagrams are very important). It is possible to go from TTT diagrams to CCT diagrams under certain circumstances, namely, if we assume that the kinetics of the transformation depends only one the fraction of the phases transformed and the temperature.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

Combined with metallography and Vickers hardness measurement, the continuous cooling transformation diagrams (CCT) of the studied steel under two different states were determined.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

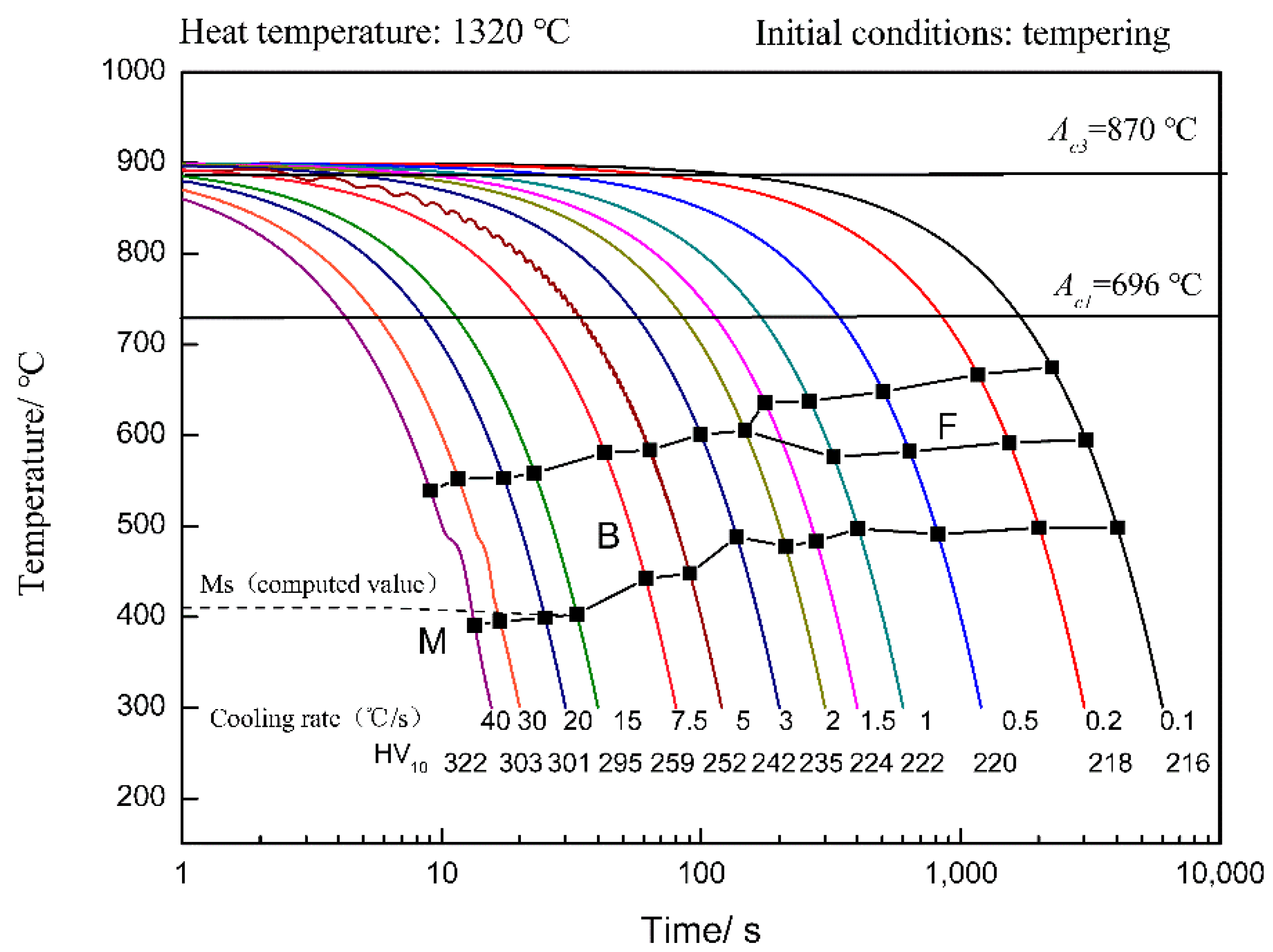

Continuous cooling transformation diagrams in synthetic weld heat-affected zone (SH-CCT diagrams) show the phase transition temperature and hardness at different cooling rates, which is an important basis for formulating the welding process or predicting the performance of welding heat-affected zone.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

Mechanical properties of the rebar are significantly influenced by area ratio and hardness of the tempered martensite. In this study, microstructure and area ratio of the tempered martensite of the rebar produced by the Tempcore process were predicted using finite volume method and a continuous cooling transformation diagram.

A gear manufacturing facility requires a recommendation for preheating to weld up a shaft to a gear flange disk. The three ( 3) foot long cylindrical machined forging made out of AISI 4340 steel is fully hardened to 300 BHN and is to be welded to a 4 inch thick mild steel (Carbon 0.15%) disk, 60 inches in diameter. The AISI/SAE 4340 shaft has an outside diameter of 10" and is inserted in a 10inch diameter hole at the center of the gear disk. The gear disk is welded 1 foot from one end of the sha...

Initially, dilatometry has been widely used in studying the kinetics of austenite-ferrite phase transformations. Application of dilatometry for constructing continuous heating transformation (CHT) and continuous cooling transformation (CCT) diagrams of steels has been outlined as a main source to understand the transformation behavior.

[Source](/r/QAnonCasualties/comments/mkl11y/) # For proper formatting, please use [Old Reddit](https://old.reddit.com/r/tabled/comments/nw85dd/) Rows: 94 (+comments) Questions|Answers :--|:-- How much is Q a result of the mega change in human society over the past ~20 years, whereby ignorant people can now connect widely via social media?|I don't think you'd have something like Q get anywhere near as big as it has without the internet. Before, people couldn't get this kind of constant affirma...

Temperature-Transformation curves (TTT, also known as Isothermal Transformation Diagram) or the Continuous Cooling Transformation diagram (CCT) to the Cooling Diagram, the user can find the structural transformations in the part cross-section including the case depth and hardness, if applicable on the CCT graph. 3. Results of investigation

Continuous cooling transformation (CCT) diagrams were developed for rapid austenitizing temperatures 25 °C above the Ac3determined by dilatometry.

So around 9am this morning, my Fiancé takes the dog out to the backyard, and notices the condenser fan isn't running, but it definitely should be because its already pushing 90F out. I go outside and check it out, fan is indeed not running but I can hear it buzzing. These leads me to believe it might not just be getting enough starting current, so I use a stick to get the fan running, and lo and behold it starts spinning. I head back inside for about 20 minutes, then decide to go check on it ...

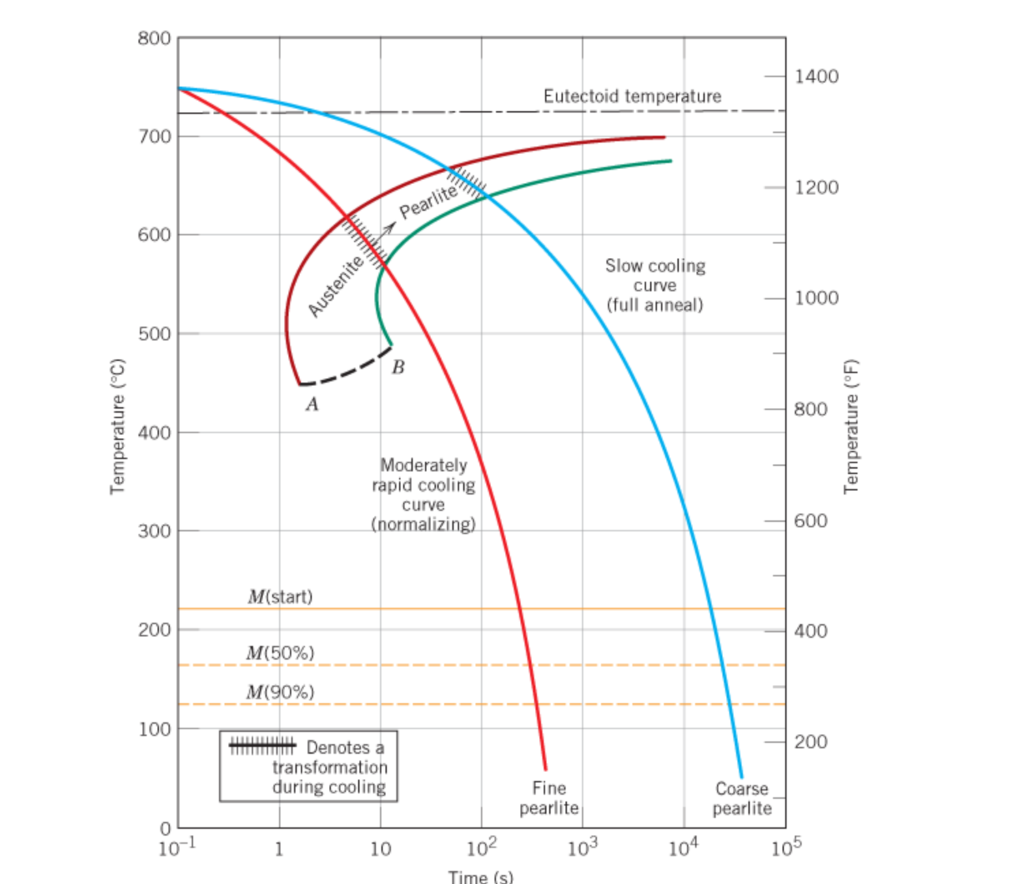

The other more useful form of a time temperature transformation diagram is the continuous-cooling transformation (CT) diagram. This differs from the IT diagram in that it is constructed by cooling small specimens at various cooling rates and measuring the temperatures at which transformations start and finish using a device called a dilatometer ...

**Wendy Darling's**. **Tommy Emu**. **Jasper Lee.** Do any of these names look familiar to you? Because I feel like I'm losing my fucking mind. I've been watching this channel for months. They've been my comfort Twitch streamers, and now they've dropped off the face of the earth. Nobody is talking about them or tweeting about them. It doesn't make any sense! I don't know where they've gone. I don't know if maybe I'm – maybe I hallucinated them? But I couldn't have, right? They're real. I kno...

**Wendy Darling's**. **Tommy Emu**. **Jasper Lee.** Do any of these names look familiar to you? Because I feel like I'm losing my fucking mind. I've been watching this channel for months. They've been my comfort Twitch streamers, and now they've dropped off the face of the earth. Nobody is talking about them or tweeting about them. It doesn't make any sense! I don't know where they've gone. I don't know if maybe I'm – maybe I hallucinated them? But I couldn't have, right? They're real. I kno...

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

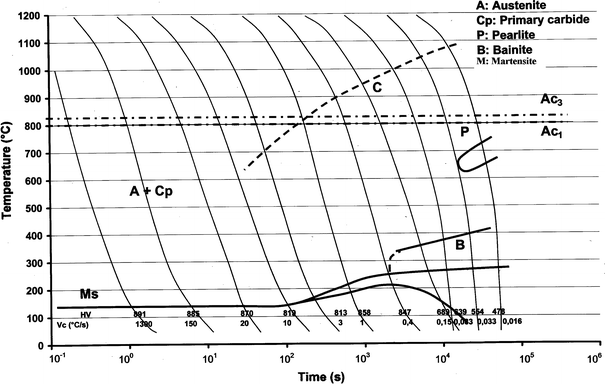

In this study, the phase transformation behaviour of the carburised layer and the matrix of 23CrNi3Mo steel was comparatively investigated by constructing continuous cooling transformation (CCT) diagram, determining the volume fraction of retained austenite (RA) and plotting dilatometric curves.

The continuous cooling transformation diagram (CCT) was calculated using a finish rolling temperature of 943 °C and an austenite grain size of 20 µm, which were the values predicted by modelling hot rolling of steel , , . The temperatures predicted for the cooling at the surface and centre of a 2.9 mm strip are also shown in Fig. 9.

In those diagrams, continuous cooling takes place while this diagram explains constant temperature transformations. TTT diagram of steel has a very important application like austempering, martempering Patenting, and isothermal annealing which is commonly employed in industry for achieving specific properties in steel. Table of Contents

1.1.3 Phase transformation in cooling. In ferrous alloys, austenite transforms into ferrite, pearlite, bainite or martensite depending on the severity of cooling portion of the thermal cycle. The phase transformations on cooling can be predicted by using appropriate continuous cooling transformation (CCT) diagram.

One of the key factors that may contribute to variations within and among parts made by this process is a difference in the material's microstructural phase and composition. A continuous cooling transformation (CCT) diagram is a useful tool that can be used with a thermal model for microstructure design and manufacturing process control.

Combined with the SHCCT diagram and microstructural observations it can be seen that the CGHAZ microstructure of simulated samples fluctuated greatly under continuous cooling transformation with different heat inputs. The sample with the heat input of 120 kJ/cm consisted of IGPF and pearlite (P).

Need more help! Figure shows the continuous cooling transformation diagram for a 1.13 wt% C iron-carbon alloy. Make a copy of this figure and then sketch and label continuous cooling curves to yield the following microstructures: (a) Fine pearlite and proeutectoid cementite. (b) Martensite. (c) Martensite and proeutectoid cementite.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theologi...

The continuous cooling transformation curve of undercooled austenite is also called CCT curve. It can be used as the basis for the analysis of austenite transformation and microstructure and properties of transformation products in continuous cooling process, and also as an important reference for the formulation of heat treatment process of steel

It does so based on a continuous cooling transformation phase diagram and a time-temperature-austenitization diagram of the considered steel. The presented method serves as a practical approach to validate simulations of the inductive austenitizing process and supports simulations of the heat treatment of the work piece.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

The satisfactory hardenability of the UniSteel can be revealed in the continuous cooling transformation diagram in fig. S6. The co-addition of Si, Mn, and Cr will increase the volume fraction of RA in the Q&P and PHS grades for better ductility (21, 22). The microalloying through Nb addition enables the NbC nanoprecipitation and the processing ...

So around 9am this morning, my Fiancé takes the dog out to the backyard, and notices the condenser fan isn't running, but it definitely should be because its already pushing 90F out. I go outside and check it out, fan is indeed not running but I can hear it buzzing. These leads me to believe it might not just be getting enough starting current, so I use a stick to get the fan running, and lo and behold it starts spinning. I head back inside for about 20 minutes, then decide to go check on it aga...

The difference between CCT and TTT curve are as follows: CCT stands for Continuous cooling transformation which is a continuous cooling curve. TTT stands for time-temperature transformation which is basically a time-temperature transformation curve. CCT curves are useful to obtain different metastable products by controlling the rate of cooling.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

In addition, the dynamic continuous cooling transformation diagram (DCCTD) of steel was established to characterize the phase transformation behavior. Materials and experiments The forged 25Cr2Ni4MoVA steel bar was used for experiments, and the composition of the steel is given in Table 1.

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

I need to make one thing clear before I go any further: I DID NOT push him! I don’t give a damn what’s being said, I didn’t push him off the ledge. Even if I had, however.... I think we’re all about to find out soon just how little it would matter anyway. I’ve seen what’s going to happen. People eating each other in the street, the sky turning red, and all around panic of the world ending. I have to say, it’s funny how people are scared of the end. Not because of any philosophical or theolog...

This investigation aims to ascertain the effect of cooling rate on transformation behavior, microstructure, hardness and low-temperature (-20 °C) impact toughness. In addition to this, CCT diagram applicable to weld CGHAZ was constructed based on the result of dilation analysis, microstructure and hardness. Experimental procedure

1. Cite two important differences between continuous-cooling transformation diagrams for plain carbon and alloy steels. 2. Briefly explain why there is no bainite transformation region on the continuous-cooling transformation diagram for an...

![PDF] Continuous Cooling Transformation (CCT) Diagrams Of ...](https://d3i71xaburhd42.cloudfront.net/6b2bd9cac4c059e360fc7bc0b57e91dd2c199ed7/2-Figure1-1.png)

0 Response to "39 continuous cooling transformation diagram"

Post a Comment